Lapped bevel gears production process

The production process of lapped bevel gears involves several steps to ensure accuracy and quality. Here is a general overview of the process:

Design: The first step is to design the bevel gears according to the specific requirements of the application. This includes determining the tooth profile, diameter, pitch, and other dimensions.

Material selection: High-quality steel or alloy materials are typically used for lapped bevel gears due to their strength and durability.

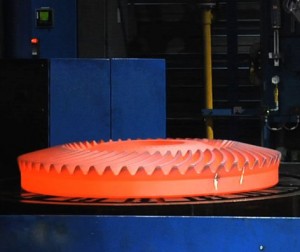

Forging:Metal is heated and shaped using compressive forces to create the desired gear shape.

Lathe turning: rough turning: material removal and shaping. Finish turning: achieve the final dimensions and surface finish of the workpiece.

Milling: The gear blanks are cut from the selected material using CNC machining. This involves removing excess material while maintaining the desired shape and dimensions.

Heat treatment: Then heat-treated to enhance their strength and hardness. The specific heat treatment process may vary depending on the material used.

OD/ID grinding: Offers advantages in terms of precision, versatility, surface finish, and cost-effectiveness

Lapping: Lapping is a crucial step in the production of bevel gears. It involves rubbing the gear teeth against a rotating lapping tool, typically made of a soft material like bronze or cast iron. The lapping process helps in achieving tight tolerances, smooth surfaces, and proper tooth contact patterns.

Cleaning process: The bevel gears may undergo finishing processes such as deburring, cleaning, and surface treatments to enhance their appearance and protect against corrosion

Inspection: After lapping, the gears undergo a thorough inspection to check for any defects or deviations from the required specifications. This may involve dimension test, chemical test, accuracy test, meshing test ect.

Marking: Part number lasered according to customer’s request for easier product identification.

Packing and warehousing:

It’s important to note that the above steps provide a general overview of the production process for lapped bevel gears. The exact techniques and processes may vary depending on the specific manufacturer and application requirements.

Post time: Oct-20-2023