There are many types of gears, including straight cylindrical gears, helical cylindrical gears, bevel gears, and the hypoid gears we are introducing today.

1)The characteristics of hypoid gears

First of all, the shaft angle of the hypoid gear is 90°, and the torque direction can be changed to 90°. This is also the angle conversion often required in the automobile, airplane, or wind power industry. At the same time, a pair of gears with different sizes and different numbers of teeth are meshed to test the function of increasing torque and decreasing speed, which is commonly referred to as “torque increasing and decreasing speed”. If a friend who has driven a car, especially when driving a manual car when learning to drive, when climbing a hill, the instructor will let you go to a low gear, in fact, it is to choose a pair of gears with a relatively large speed, which is provided at low speeds. More torque, thus providing more power to the vehicle.

What are the characteristics of hypoid gears?

Changes in the transmission torque angle

As mentioned above, the angular change of torque power can be realized.

Able to withstand greater loads

In the wind power industry, the automotive industry, whether it is passenger cars, SUVs, or commercial vehicles such as pickup trucks, trucks, buses, etc., will use this type to provide greater power.

More stable transmission, low noise

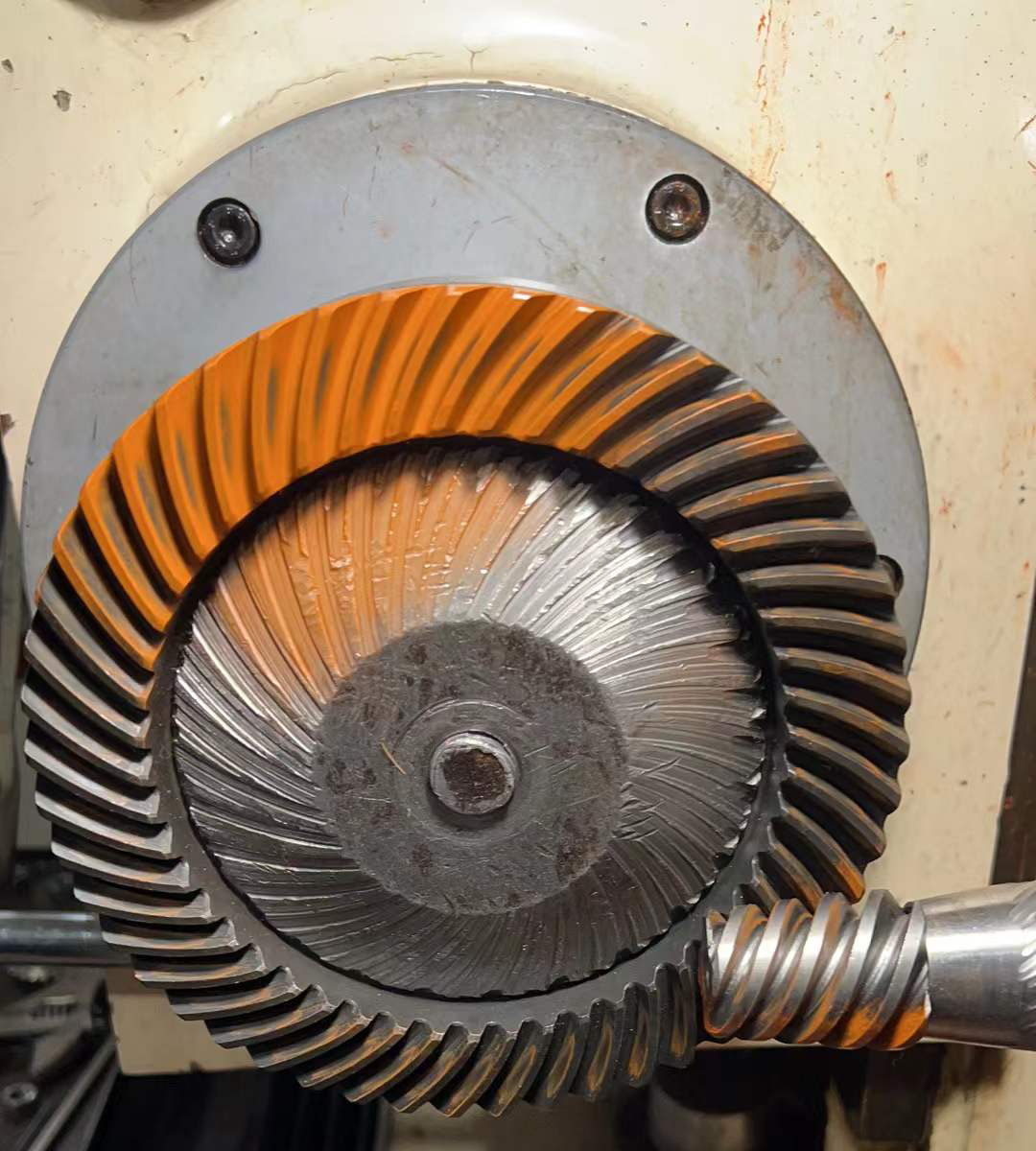

The pressure angles of the left and right sides of its teeth can be inconsistent, and the sliding direction of the gear meshing is along the tooth width and tooth profile direction, and a better gear meshing position can be obtained through design and technology, so that the entire transmission is under load. The next is still excellent in NVH performance.

Adjustable offset distance

Due to the different design of the offset distance, it can be used to meet different space design requirements. For example, in the case of a car, it can meet the ground clearance requirements of the vehicle and improve the pass ability of the car.

2)Two processing methods of hypoid gears

The quasi-double-sided gear was introduced by Gleason Work 1925 and has been developed for many years. At present, there are many domestic equipment that can be processed, but the relatively high-precision and high-end processing is mainly made by foreign equipment Gleason and Oerlikon . In terms of finishing, there are two main gear grinding processes and grinding processes, but the requirements for the gear cutting process are different .For the gear grinding process, the gear cutting process is recommended to use face milling, and the grinding process is recommended to face hobbing .

The gears processed by the face milling type are tapered teeth, and the gears processed by the face rolling type are equal-height teeth, that is, the tooth heights at the large and small end faces are the same.

The usual processing process is roughly pre-heating, after heat treatment, and then finishing. For the face hob type, it needs to be ground and matched after heating. Generally speaking, the pair of gears ground together should still be matched when assembled later. However, in theory, gears with gear grinding technology can be used without matching. However, in actual operation, considering the influence of assembly errors and system deformation, the matching mode is still used.

3)The design and development of the triple hypoid is more complicated, especially in the operating conditions or high-end products with higher requirements, which require the strength, noise, transmission efficiency, weight and size of the gear. Therefore, in the design stage, it is usually necessary to integrate multiple factors to find a balance through iteration. In the development process, it is also usually necessary to adjust the tooth print within the allowable variation range of the assembly to ensure that the ideal performance level can still be reached under the actual conditions due to the accumulation of the dimensional chain, system deformation and other factors.

Post time: May-12-2022