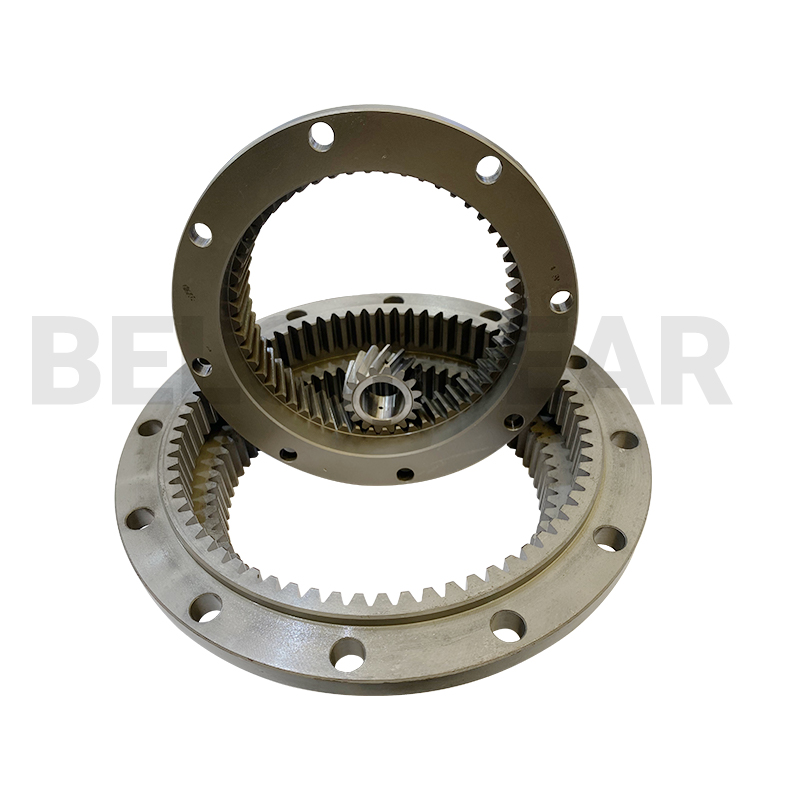

Internal gears are a type of gear where the teeth are cut on the inside of a cylinder or cone, as opposed to external gears where the teeth are on the outside. They mesh with external gears, and their design enables them to transmit motion and power in various mechanical systems.

There are several applications for internal gears:

- Planetary Gear Systems: Internal gears are commonly used in planetary gear systems, where they mesh with the sun gear and the planet gears. This arrangement allows for compact and versatile gear trains, often used in automotive transmissions and industrial machinery.

- Power Transmission: Internal gears can be used to transmit power between parallel or intersecting shafts. They are often employed in situations where space constraints or specific torque requirements necessitate their use.

- Speed Reduction or Increase: Internal gears can be used to increase or decrease rotational speed depending on their configuration and meshing with external gears.

- Motion Control: In robotics and automation, internal gears are utilized for precise motion control, ensuring smooth and accurate movement in robotic arms, CNC machines, and other automated systems.

- Differential Mechanisms: Internal gears can also be found in differential mechanisms, such as those used in automotive drivetrains, to distribute power and torque between wheels while allowing them to rotate at different speeds.

- In robotics and automation, internal gears are widely used to achieve precise movements within limited spaces. Robotic arms, for example, frequently use internal gears in their actuators to provide accurate positioning with minimal backlash, enabling smoother, more controlled motion. The compact nature of internal gears helps engineers integrate complex gear systems in smaller assemblies, allowing robots to maintain a high degree of agility and efficiency without sacrificing power or control.

- Internal gears are also a popular choice in electric vehicles (EVs), especially in gearboxes designed to handle high rotational speeds. EV motors often operate at much higher speeds than internal combustion engines, so internal gears, combined with planetary gear systems, are essential for reducing speed while amplifying torque. This setup enhances energy efficiency, leading to smoother power delivery and extended battery life.

- In printing presses and textile machinery, where high precision is critical, internal gears are used in systems that need to maintain synchronized rotation and speed. The internal gear setup helps achieve consistency and precision in motion, contributing to the quality of the final product, be it printed materials or textiles. Their compact form and efficient load-sharing capabilities enable these machines to operate at high speeds without risking misalignment or excessive wear.

Additionally, medical equipment like surgical robots and imaging systems often utilize internal gears in their actuators for precise, controlled movement within compact spaces. Internal gears help maintain accuracy and stability, which are vital for delicate operations, diagnostics, and patient safety.

The design and manufacturing of internal gears can be more complex than external gears due to the difficulty of accessing the inside of the gear during machining. However, they offer advantages in certain applications, such as compactness, increased torque transmission capacity, and smoother operation.

Post time: Apr-30-2024