PERFORMANCE CHARACTERISTICS AND BEST USES

Hypoid gears are a type of spiral bevel gear that are used to transmit rotational power between two shafts at right angles. Their efficiency at transferring power is typically 95%, especially at high reductions and low speeds, while efficiency for worm gears varies between 40% and 85%. Greater efficiency means smaller motors can be used, reducing energy and maintenance costs.

Hypoid gears vs. bevel gears

Hypoid gears belong to the bevel gear family, which includes two categories:

straight teeth and spiral teeth. Although hypoid gears technically belong to the

spiral teeth category, they have enough specific attributes to make up their own

category.

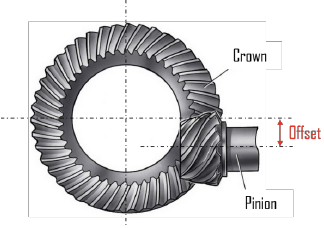

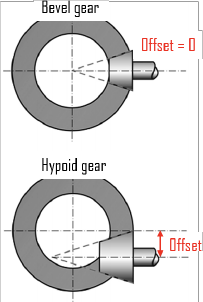

In contrast with a standard bevel gear, the mating gear shafts for hypoid gear

sets do not intersect, because the small gear shaft (pinion) is offset from the

larger gear shaft (crown). The axis offset allows the pinion to be larger and have

a greater spiral angle, which increases the contact area and the tooth strength.

While sharing a similar shape, the main difference between hypoid and bevel gears is the offset of the pinion. This offset allows a greater flexibility for the design and increases the pinion diameter and the contact ratio (the average number of tooth pairs in contact is typically 2.2:1 to 2.9:1 for hypoid gear sets). As a result, higher levels of torque can be transmitted with lower noise levels. However, hypoid gears are usually less efficient (90 to 95%) than a similar set of spiral bevel gearing (up to 99%). The efficiency decreases as the offset increases, and special attention must be given to lubrication to reduce friction, heat, and wear due to the sliding action of hypoid gear teeth.

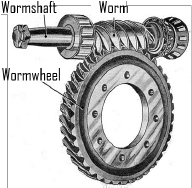

Hypoid gears vs. worm gears

Hypoid gears are positioned as an intermediate option, between a worm gear and a bevel

gear. For decades, worm gears were the popular choice for right angle reducers, because they were robust and relatively inexpensive. Today, hypoid gears are a better alternative for many reasons. They have a higher efficiency, especially at high reductions and low speeds, which leads to energy savings and also makes hypoid gear reducers more suited for applications with space constraints.

How hypoid gears work in reducers

Single stage hypoid reducers can achieve reductions with ratios of 3:1 to 10:1. In comparison to straight or spiral bevel reducers, which need an additional planetary stage to achieve the reduction, the single stage hypoid is well suited for compact applications that fall in this range of reduction ratios.

Hypoid gears can be combined with planetary gears in multiple stage gearboxes to reach

higher reduction ratios, typically up to 100:1 with a single additional planetary stage. In that case, hypoid gears should be chosen over bevel gears for the 90° angle transmission, if the configuration of the system requires non-intersecting shafts or if higher torques need to be transmitted with low noise levels.

When compared to worm gear reducers, hypoid reducers are a better option in terms of efficiency and heat generation. They require less maintenance and fit into tighter places while delivering the same amount of torque. For long term cost savings, hypoid reducers are an alternative to worm gear reducers that should be considered.

Why choose hypoid gearboxes from belongear?

Hypoid gearing is a relatively new player in the precision servo gearbox market. However, the combination of its high levels of efficiency, accuracy, and torque, along with its low noise and compact, right angle design make hypoid gearing an increasingly popular choice for automation and motion control. Precision hypoid gearboxes from belongear have the properties required to ensure optimal performance in many servo motor applications.

Post time: Jul-21-2022