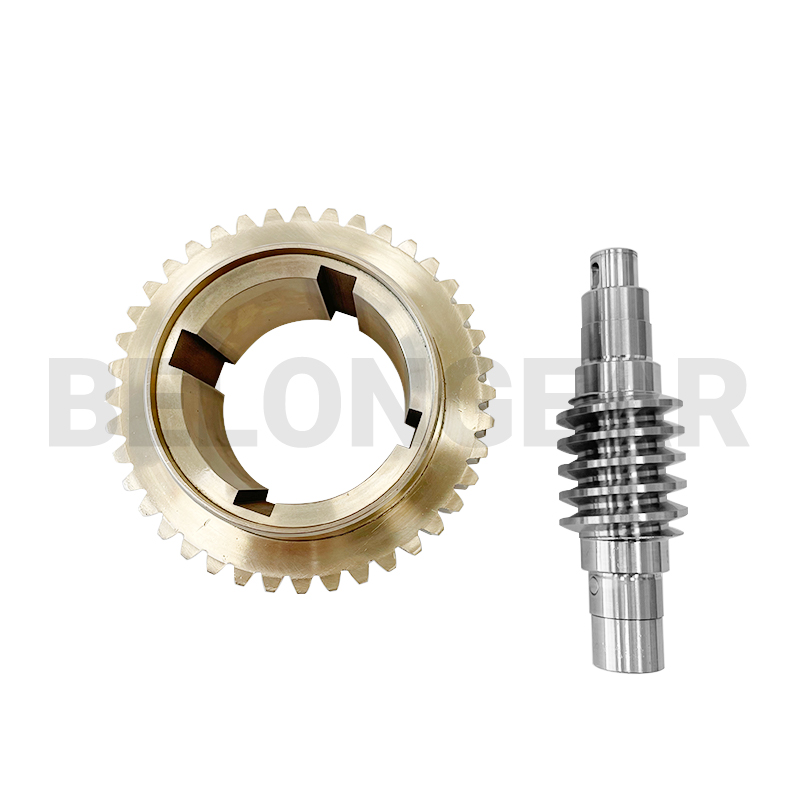

What is Double Enveloping Worm Gear?

A double enveloping worm gear is a specialized gear system that provides enhanced efficiency, load capacity, and precision compared to conventional worm gears. It is commonly used in applications requiring high torque transmission and minimal backlash, such as robotics, aerospace, heavy machinery, and precision equipment.

Understanding the Design

A double enveloping worm gear differs from a standard worm gear in its unique geometry. Traditional worm gears consist of a cylindrical worm engaging with a concave gear. However, in a double enveloping system, both the worm and the gear wrap around each other, increasing the contact area and improving load distribution. This dual enveloping feature allows for greater torque transfer, reduced wear, and enhanced efficiency.

The worm in a double enveloping system typically has an hourglass shape, meaning its diameter varies along its length. The gear (also called the worm wheel) has a concave profile that closely matches the contour of the worm. This results in more teeth being engaged at any given time, which leads to better force distribution and higher load-bearing capability.

Advantages of Double Enveloping Worm Gears

- Increased Load Capacity – The greater contact area allows for higher torque transmission and the ability to handle heavier loads.

- Higher Efficiency – Compared to standard worm gears, the improved engagement reduces friction and energy loss, leading to better efficiency.

- Reduced Wear and Longer Lifespan – The even distribution of force minimizes localized wear, extending the gear system’s lifespan.

- Improved Precision and Stability – These gears provide lower backlash, which enhances positioning accuracy, making them ideal for precision machinery.

- Smooth and Quiet Operation – The enhanced meshing characteristics contribute to quieter operation and reduced vibration.

Applications of Double Enveloping Worm Gears

Due to their superior characteristics, double enveloping worm gear are widely used in industries requiring high-performance motion transmission. Some common applications include:

- Aerospace – Used in actuators and landing gear mechanisms.

- Industrial Machinery – Found in heavy-duty conveyors, presses, and automated systems.

- Defense and Robotics – Provides precision control in robotic arms and military equipment.

- Automotive – Used in steering systems and specialized transmission units.

- Oil and Gas Industry – Deployed in drilling rigs and extraction equipment for high load applications.

Challenges and Considerations

While double enveloping worm gears offer numerous advantages, they also have some limitations:

- Complex Manufacturing – The intricate geometry requires precision machining, making them more expensive to produce than standard worm gears.

- Higher Initial Cost – The enhanced performance comes with increased manufacturing and material costs.

- Lubrication Requirements – Proper lubrication is crucial to maintain efficiency and prevent premature wear.

The double enveloping worm gear is an advanced gear system that outperforms conventional worm gears in load capacity, efficiency, and durability. Despite its higher cost and complexity, its benefits make it an ideal choice for critical applications in aerospace, defense, and heavy machinery. When precision, strength, and longevity are required, the double enveloping worm gear remains a superior solution in modern engineering

Post time: Feb-05-2025