When it comes to high torque industrial applications, gear material selection plays a critical role in determining both performance and longevity.

At Belon Gears, we specialize in precision engineered gear solutions, and one of the most common questions we encounter from engineers and OEM partners is: “What’s the best material for high torque gears?”

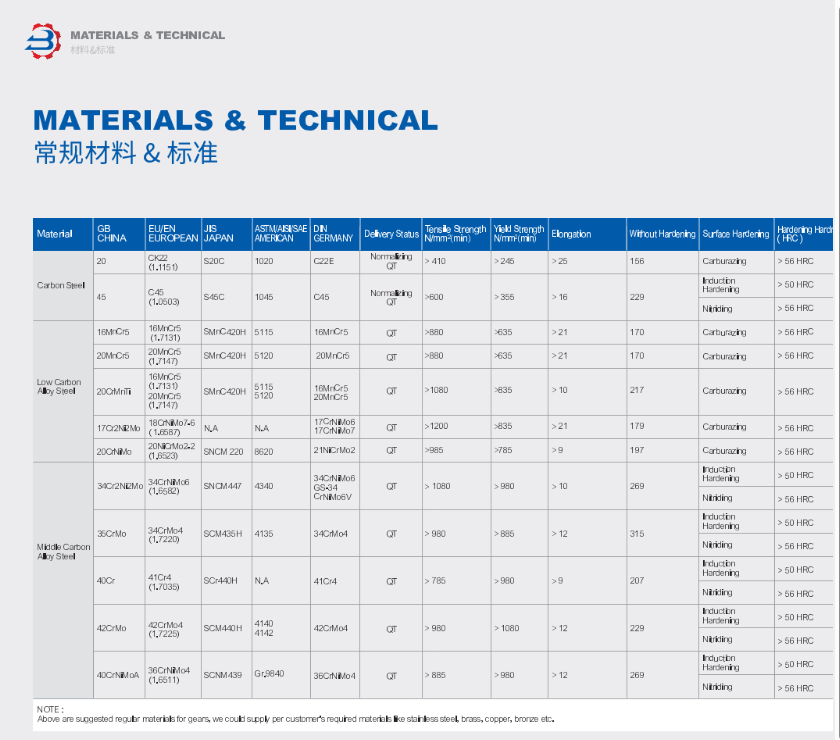

In most heavy duty applications robotics, mining, automation, or power transmission—alloy steels are the go to choice. Materials like 42CrMo4, 18CrNiMo7-6, and 4140 steel offer an ideal balance between core strength, toughness, and fatigue resistance.

Gear engineering solutions Belon gears

For high torque performance, we recommend:

1. 42CrMo4 (AISI 4140): Known for its high strength and impact resistance. Ideal for gears subjected to shock loads and continuous stress.

2. 18CrNiMo7-6: This case-hardening steel delivers excellent wear resistance and high surface hardness after carburizing, making it perfect for precision-ground gears that require tight tolerances.

3. Nitrided or carburized surfaces: Enhance surface hardness without compromising the ductile core, which is essential for shock absorption in torque-heavy systems.

At Belon Gears, we combine material science, heat treatment expertise, and tight tolerance CNC machining to produce high performance gears tailored for demanding environments. For example, in one of our robotic joint drive applications, we used nitrided 42CrMo4 helical gears and achieved excellent wear resistance under continuous torque over 400Nm.

If you’re designing a drivetrain, actuator, or gearbox that demands strength, precision, and durability, choosing the right gear material is key. Let our engineering team assist you in selecting the optimal solution.

Contact Belon Gears for expert gear material consultation and fully customized solutions.

Post time: Apr-24-2025