Which Transmissions Use Planetary Gears?

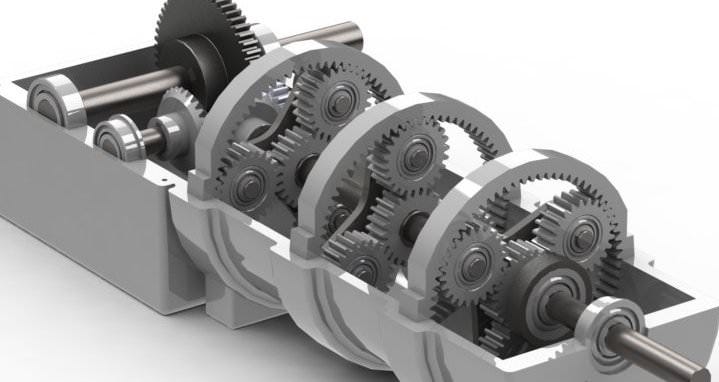

Planetary gears also known as epicyclic epicycloidal gear , are highly efficient and compact mechanisms widely used in various types of transmissions due to their ability to handle high torque in a small package. These gears consist of a central sun gear, surrounding planet gears, and an outer ring gear that moves in harmony, allowing for different speed ratios and power outputs. In this blog post, we will explore which types of transmissions use planetary gears and why they are preferred in many modern applications.

1. Automatic Transmissions in Vehicles

One of the most common applications of planetary gears is in automatic gears transmissions for vehicles. Automatic transmissions are designed to seamlessly change gears based on speed and load conditions without manual intervention. The planetary gear system plays a crucial role in this process by providing multiple gear ratios with a compact design.

In an automatic transmission, the sun gear, planet gears, and ring gear can be selectively locked and unlocked to create different torque outputs and speed ratios. By manipulating these components, the transmission can shift gears smoothly and efficiently. The compactness of planetary gears allows manufacturers to fit more complex gear systems into smaller spaces, making them ideal for vehicles where space is limited.

what is planetary gears

strength analysis of planetary gears

how is planetary gear set working

2. Hybrid and Electric Vehicle Transmissions gears

With the rise of hybrid and electric vehicles (EVs), planetary gears are becoming even more essential. In hybrid transmissions, planetary gear systems allow the vehicle to switch between electric and gasoline power or combine them seamlessly for optimal performance. Planetary gears enable smooth transitions between different driving modes, such as pure electric, hybrid, and regenerative braking.

In electric vehicle transmissions, which typically operate with fewer gear ratios than traditional cars, planetary gears can be used to optimize torque distribution and enhance vehicle performance. The efficiency and durability of planetary gear systems help EVs achieve greater driving range and performance with fewer mechanical components.

3. Industrial Machinery gears

Planetary gears are also extensively used in industrial machinery, particularly in equipment that requires high torque in a compact form. For instance, they are employed in conveyor belts, cranes, and heavy-duty drilling equipment. In these applications, the planetary gear setup provides the necessary strength to handle heavy loads while maintaining precision.

In construction equipment such as excavators, planetary gear systems are used in the drive mechanisms to provide the powerful torque needed for digging and lifting. The rugged design and high load capacity make planetary gears ideal for industrial use where both efficiency and reliability are essential.

4. Wind Turbine Gearboxes

Planetary gears are also utilized in wind turbine gearboxes, where they help convert the low rotational speed of the turbine blades into the high speed needed to generate electricity. The compact design of planetary gear systems makes them suitable for wind turbines, where space and weight constraints are critical factors.

Wind turbines require a gear system that can efficiently handle variable loads and speeds while maintaining reliability over long periods. Planetary gears excel in these conditions, offering a high level of precision and durability, which is essential for renewable energy applications.

Post time: Oct-09-2024