Worm sshaft often used in conjunction with a worm gear, is integral to many mechanical systems due to its unique properties and advantages. Here are some common applications:

Elevators and Lifts Gear: Worm shafts are used in the gear mechanisms of elevators and lifts to provide smooth and controlled motion. Their self locking capability helps prevent the lift from falling in case of a power failure.

Conveyor Systems Gear: Worm shaft are employed in conveyor systems for material handling. They offer precise speed control and can

handle high torque applications.

Automotive Steering Systems Gear: In automotive applications, worm shafts are part of the steering mechanism, where they provide smooth

and reliable operation with a high reduction ratio.

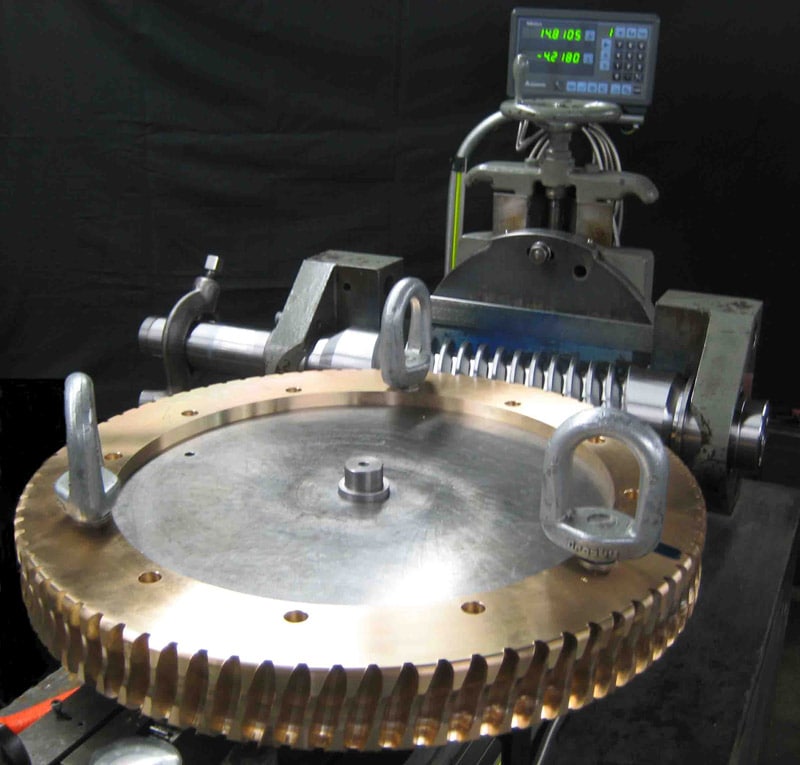

Machinery and Industrial Equipment Gear: Various machines and industrial equipment use worm shafts for motion control and power

transmission. They are valued for their ability to achieve high torque reduction ratios in a compact form.

Gates and Valves Gear: Worm shafts are used in gate and valve actuators to control the opening and closing mechanisms. Their high torque

and self locking nature make them ideal for these applications.

Winches and Hoists Gear: In winches and hoists, worm shafts provide the necessary torque to lift heavy loads, ensuring safety and stability

through their self-locking properties.

Packaging Machinery Gear: Worm shafts are used in packaging machinery to control the movement of various components, ensuring precise

and consistent operation.

Robotics: Worm shafts are employed in robotic joints and actuators, offering precise control and positioning.

Textile Machinery Gear: In textile machinery, worm shafts help control the movement of various parts, ensuring accurate and efficient operation.

Agricultural Machinery Gear: Worm shafts are used in agricultural machinery for various applications, such as controlling the movement of

seeders, harvesters, and other equipment.

The key advantages of worm shafts in these applications include their ability to provide high reduction ratios, smooth and quiet

operation, self-locking capabilities, and compact design. These characteristics make them suitable for a wide range of industrial and

mechanicalsystems.

Post time: Jun-07-2024