-

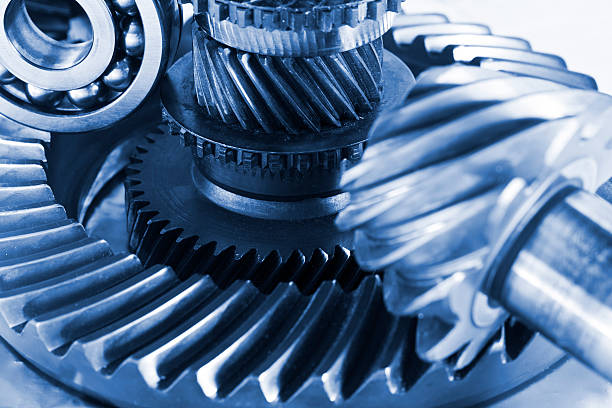

The advantages of gleason bevel gear

Gleason bevel gears, known for their precision and performance, offer several advantages that make them a popular choice for various industrial applications: High Load Capacity: Due to their unique tooth shape, Gleason bevel gears can handle high torque loads effectively, which is crucial for ap...Read more -

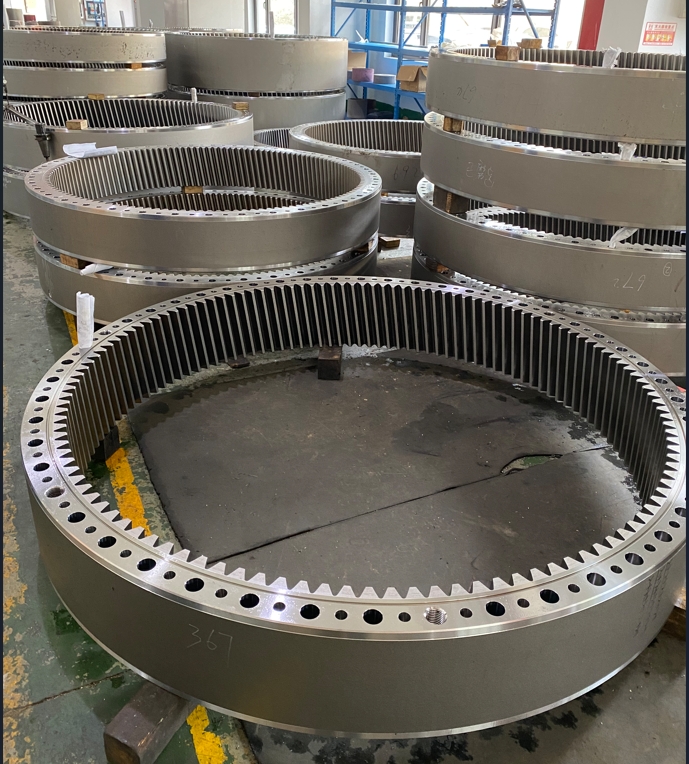

The wide application of internal gears

Internal gears are a type of gear where the teeth are cut on the inside of a cylinder or cone, as opposed to external gears where the teeth are on the outside. They mesh with external gears, and their design enables them to transmit motion and power in various mechanical systems. There are sever...Read more -

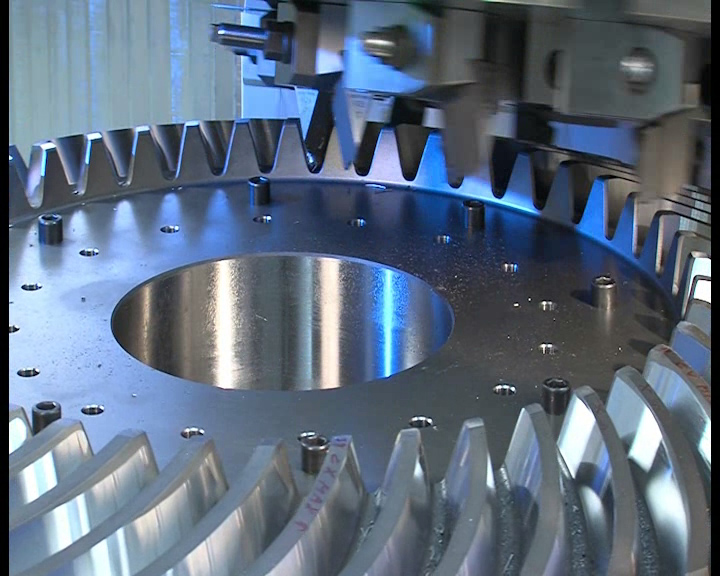

The application of cylindrical gear in wind power

Cylindrical gears play a crucial role in the operation of wind turbines, especially in converting the rotational motion of the wind turbine blades into electrical energy. Here’s how cylindrical gears are applied in wind power: Step-up Gearbox: Wind turbines operate most efficiently at a r...Read more -

The Art of Bevel Gear Hobbing

In the intricate world of mechanical engineering, every gear counts. Whether it’s transferring power in an automobile or orchestrating the movement of industrial machinery, the precision of each gear tooth is paramount. At Belon, we take pride in our mastery of bevel gear hobbing, a proces...Read more -

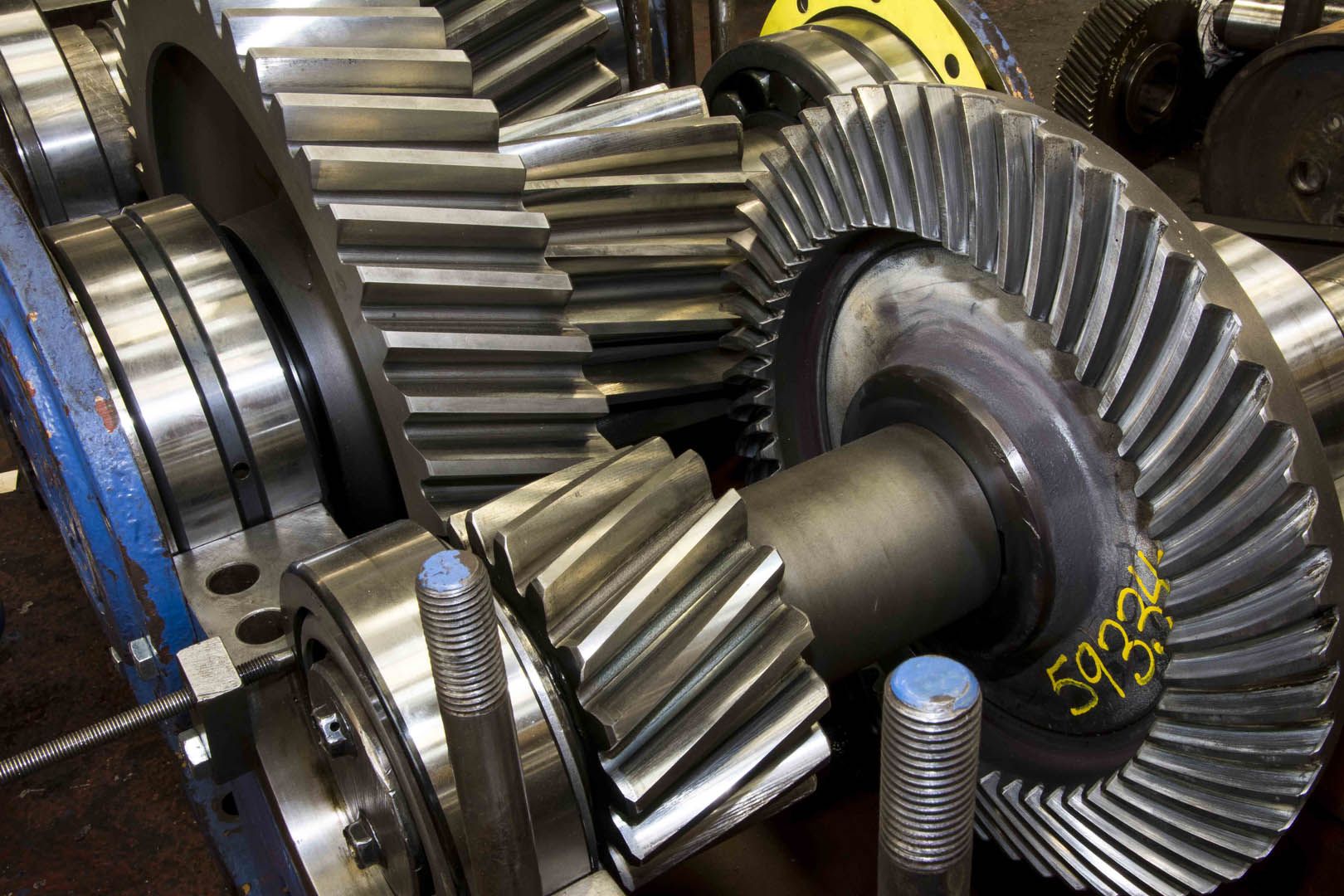

Bevel Helical Gear in Reducers

In the realm of mechanical power transmission, the utilization of gears is ubiquitous, with each type offering unique advantages for specific applications. Among these, the bevel helical gear, particularly when integrated into reducers, stands out as a pinnacle of engineering ingenuity. A bevel g...Read more -

Bevel Gear Design Solutions in Mining Gearbox

In the demanding world of mining, equipment reliability is paramount. Gearboxes, critical components in mining machinery, must withstand heavy loads, high torque, and harsh operating conditions. One key aspect of ensuring gearbox durability and efficiency is the design of the bevel gears they con...Read more -

Bevel Gear Gearing for Heavy Equipment Industrial Machinery

Bevel gear units in heavy equipment play a vital role in the overall functionality and performance of these powerful machines. Bevel gears, including helical bevel gears and spiral bevel gears, are widely used in heavy equipment to transmit power and motion between shaft...Read more -

The Precision Art of Forging Straight Bevel Gears for Tractors

In the ever-evolving landscape of agriculture, the efficiency and reliability of farming machinery play a pivotal role in shaping the industry’s future. Tractors, the workhorses of modern farming, have undergone significant advancements to meet the increasing demands for productivity. Bevel...Read more -

Can bevel gear replace worm gear?

The choice between using a worm gear or a bevel gear in a mechanical system can have a significant impact on its performance, efficiency, and overall cost. Both types of gears have their unique characteristics and strengths, so it is essential to understand the differences between them when decid...Read more -

Is bevel gear used in motorcycles?

Motorcycles are marvels of engineering, and every component plays a crucial role in their performance. Among these components, the final drive system is paramount, determining how power from the engine is transmitted to the rear wheel. One of the key players in this system is the bevel gear, a ty...Read more -

What is the reason behind using spiral bevel gears in accessory gearbox design?

Spiral bevel gears are commonly used in accessory gearbox design for several reasons: 1. Efficiency in Power Transmission: Spiral bevel gears offer high efficiency in power transmission. Their tooth configuration allows for smooth and gradual contact between teeth, minim...Read more -

why planet carrier is important in the planetary gearbox system?

In a planetary gearbox system, the planet carrier plays a crucial role in the overall function and design of the gearbox. A planetary gearbox consists of several components, including a sun gear, planet gears, ring gear, and the planet carrier. Here’s why the planet carrier is important: Su...Read more