-

Explore the role of miter gears in machinery

Miter gears assume a vital role in machinery as they serve as essential components for transmitting power between shafts that intersect at a right angle. The design of these gears allows for a right angle change in the direction of rotation, making them suitable for various applications. HereR...Read more -

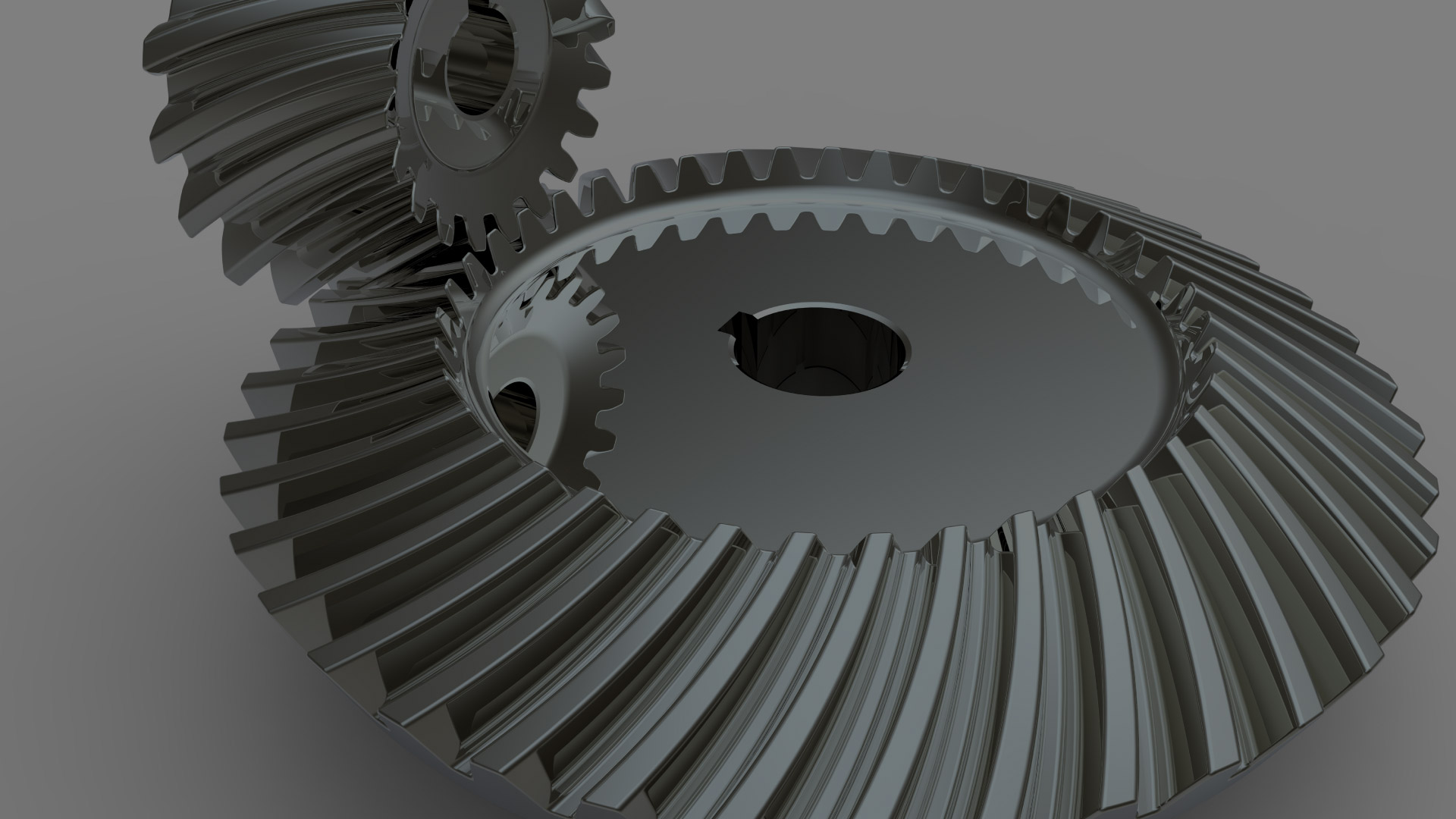

Spiral bevel gear more often used in main gearboxes, Why?

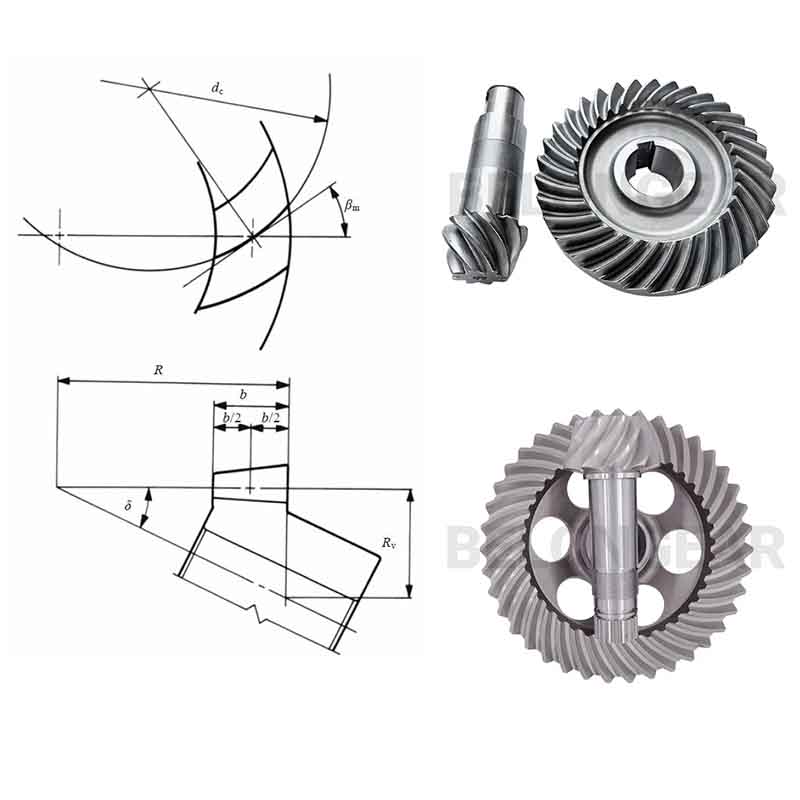

I. Basic Structure of Bevel Gear Bevel gear is a rotary mechanism used to transmit power and torque, usually composed of a pair of bevel gears. The bevel gear in the main gearbox consists of two parts: the large bevel gear and the small bevel gear, which are located on the input shaft and output...Read more -

Bevel gear reverse engineering

Bevel gear reverse engineering Reverse engineering a gear involves the process of analyzing an existing gear to understand its design, dimensions, and features in order to recreate or modify it. Here are the steps to reverse engineer a gear: Acquire the gear: Obtain the physical gear that...Read more -

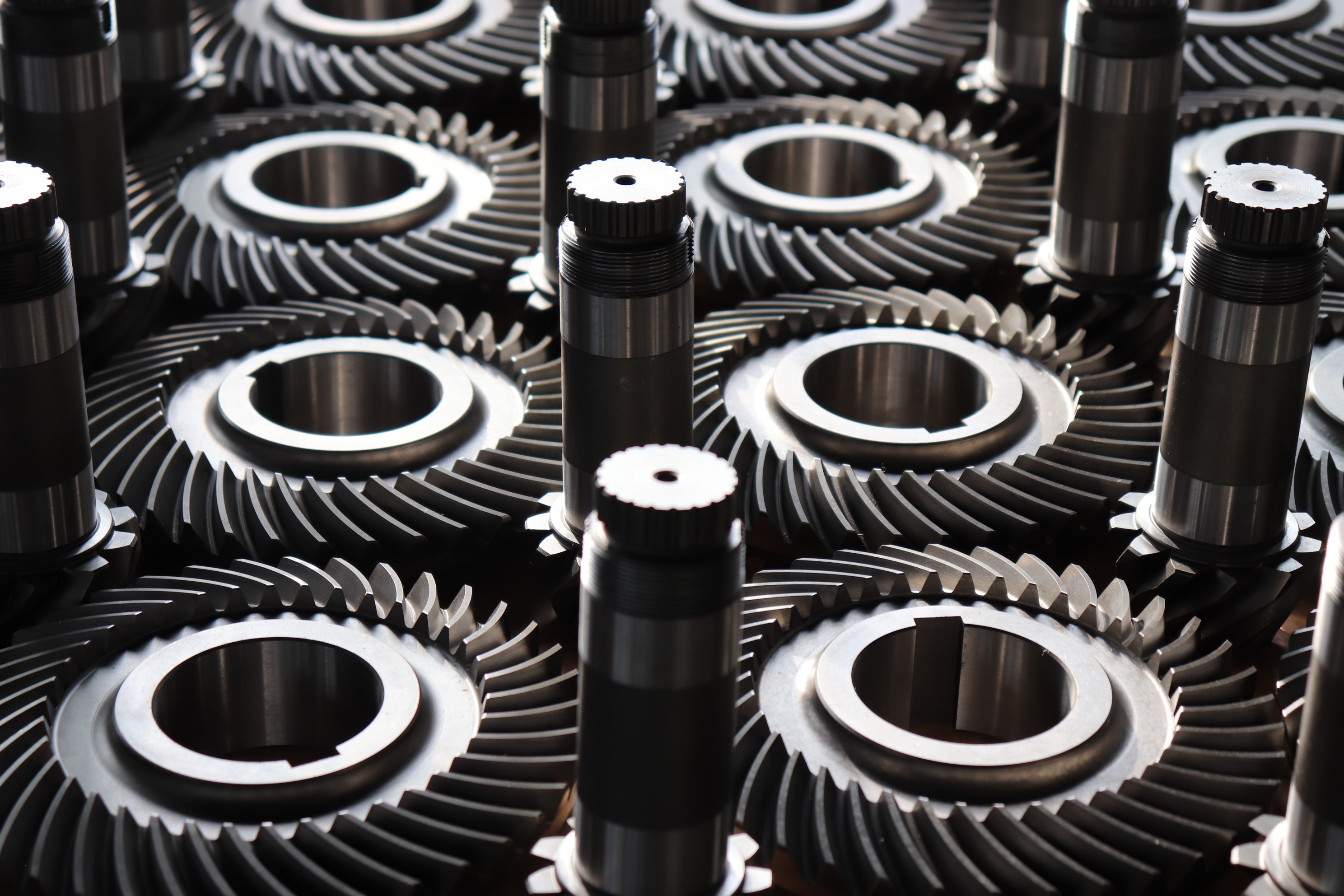

Lapped bevel gears production process

Lapped bevel gears production process The production process of lapped bevel gears involves several steps to ensure accuracy and quality. Here is a general overview of the process: Design: The first step is to design the bevel gears according to the specific requirements of the application...Read more -

Powder metallurgy gears

Powder metallurgy gears Powder metallurgy is a manufacturing prat involves compacting metal powders under high pressure and then sintering them at high temperatures to form solid parts. Powder metal gears are widely used in various industries such as automotive, industrial equipment and power tra...Read more -

Application of Large Size Bevel Gears in Crusher

Application of Large Size Bevel Gears in Crusher Large bevel gears are used to drive crushers for processing ore and minerals in the hard rock mining and mining industries. The most common of these machines are rotary crushers and cone crushers. Rotary crushers are often the first step after init...Read more -

Spiral bevel gears transmission

Spiral bevel gears transmission Spiral bevel gear transmission is a common gear transmission, which is usually used in high precision and high load applications. 一. Fundamental The spiral bevel gear transmission consists of a conical gear with helical teeth and a conical gear with helical teeth ...Read more -

Production of Straight Bevel Gears: Precision Engineering and Belon gears Manufacturing Excellence

Precision straight bevel gears application are widely used in many industries, including automotive, industrial, commercial, and material handling. Some applications of straight bevel gears include:Other applications of straight bevel gears include: Food canning and pack...Read more -

Finding the ideal material for gears

Finding the ideal material for gears When designing and manufacturing gears, the materials used will depend on what type of gear is being made and how and where it will be used. There are many kinds of raw materials commonly used in gear structures, and each material has its best mechanical prope...Read more -

Gear Shaft Types Decoded

In the realm of mechanical engineering, the gear shaft plays a pivotal role as a crucial transmission component. Gear shafts can be classified into two types based on their axial shape: crankshaft (curved) and straight shaft. Furthermore, they ...Read more -

How do Gear Ratios Work?

Gear ratios play a crucial role in the functioning of various mechanical systems, from bicycles to automobiles and industrial machinery. Understanding how gear ratios work is fundamental to appreciating the mechanics behind efficient power transfer. What are Gear Ratios...Read more -

How to design a gear?

A series of factors need to be considered in the design of gears, including the type of gear, module, number of teeth, tooth shape, etc. 1、Determine the gear type: Determine the type of gear based on the application requirements, such as spur gear, helical gear, worm g...Read more