We believe in: Innovation is our soul and spirit. Excellent is our life. Buyer want is our God for OEM Customized 1module 20teeth with 1module 60 Teeth 1: 3 Speed Ratio Precision Spiral Bevel Gear 45 Steel Hardened 90 Degree Pinion, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We believe in: Innovation is our soul and spirit. Excellent is our life. Buyer want is our God for 1: 3 and Spiral Bevel Gear, Our company has already have pass the ISO standard and we are fully respect our customer ‘s patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

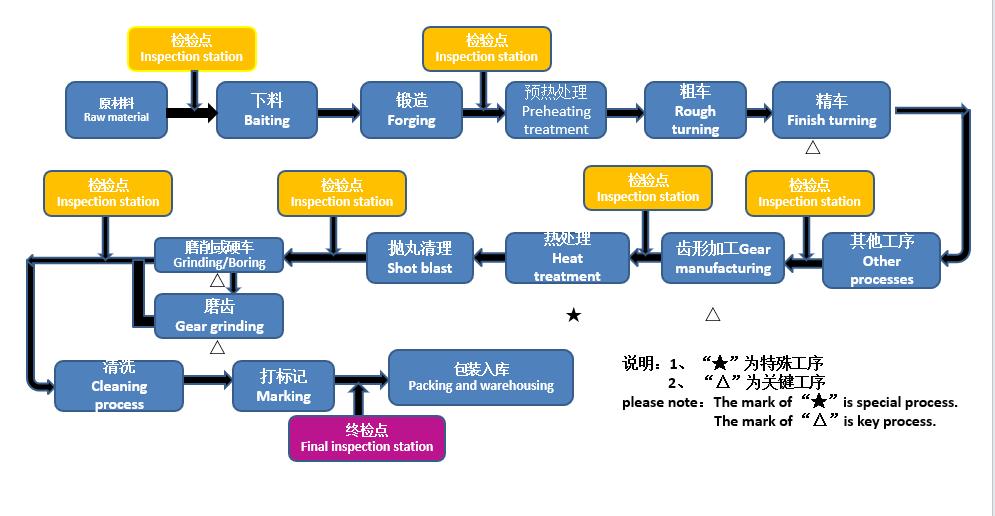

Production Process of the conical pinion shaft :

How to control the process quality and when to do the process inspection process ? This chart is clear to view .The important process for cylindrical gears .Which reports should be created during each process ?

Manufacturing Plant

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

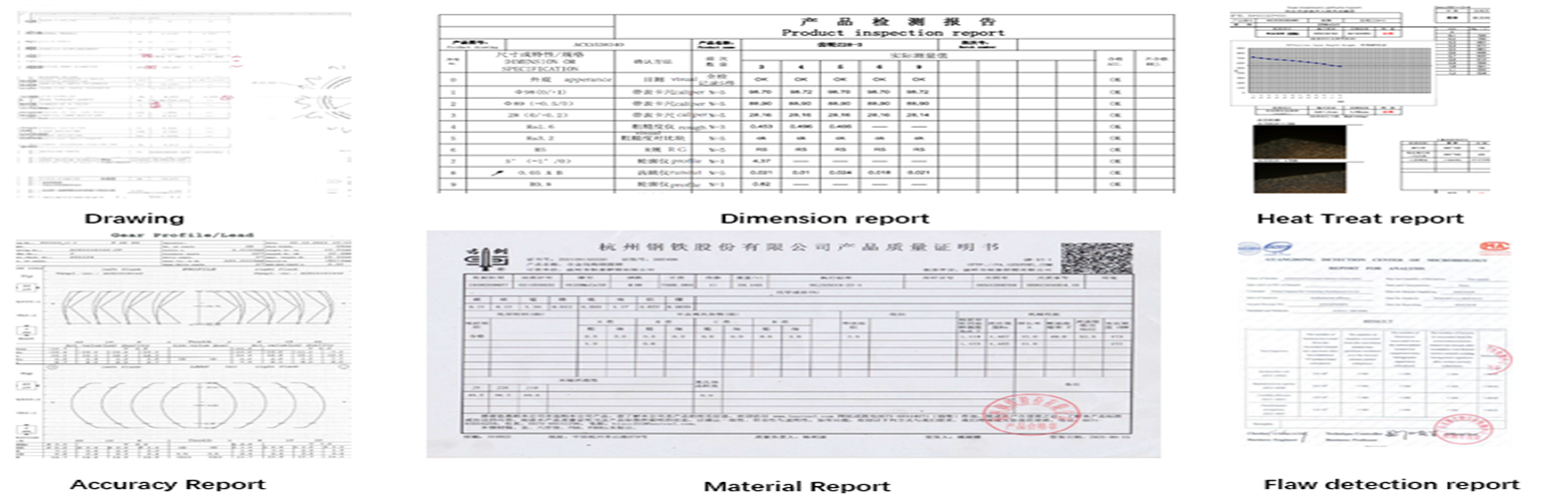

Reports

We will provide below reports also customer’s required reports before every shipping for customer to check and approve .

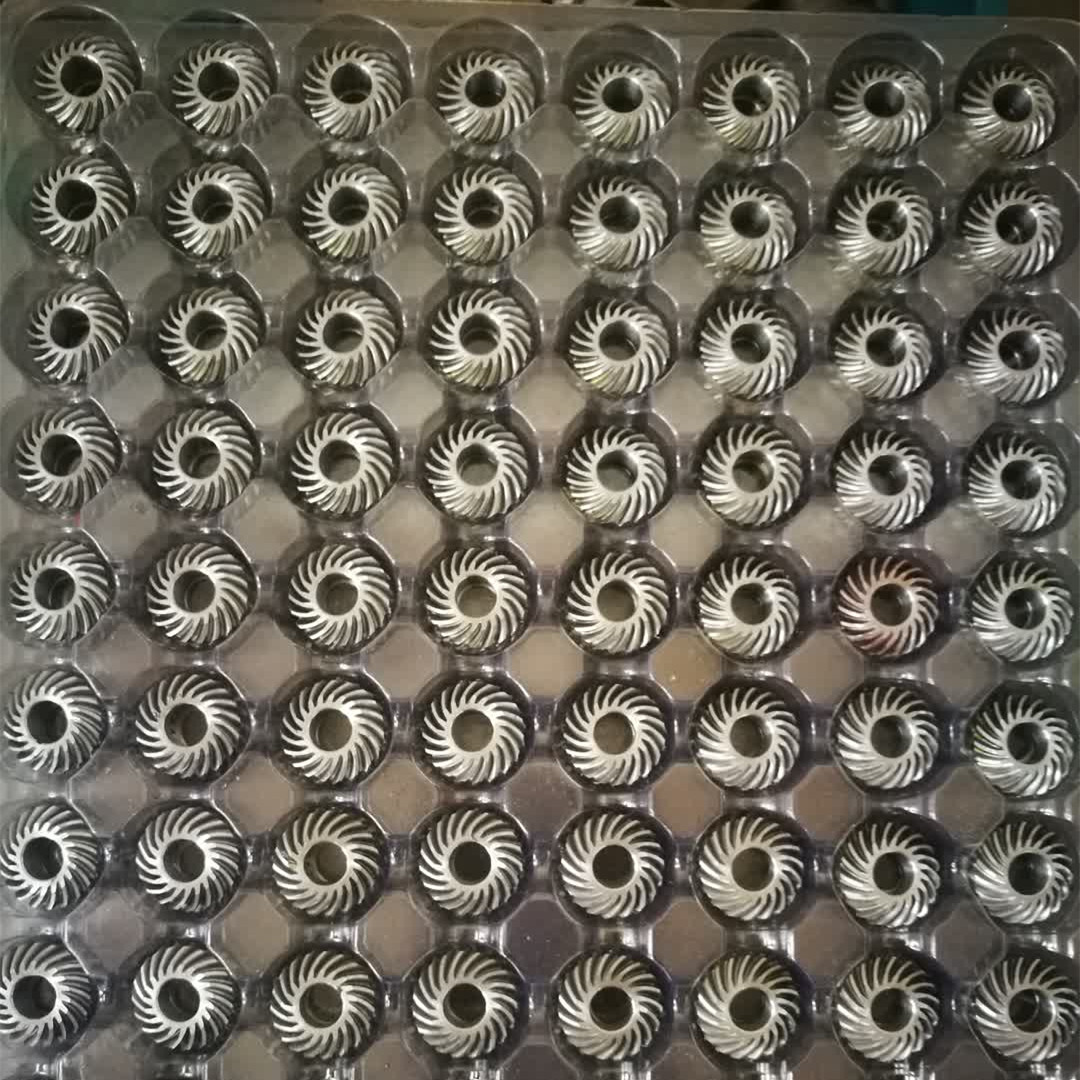

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

mining ratchet gear and spur gear

small helical gear motor gearshaft and helical gear

left hand or right hand helical gear hobbing

helical gear cutting on hobbing machine

helical gear shaft

helical gear grinding

worm wheel and helical gear hobbing

single helical gear hobbing

16MnCr5 helical gearshaft & helical gear used in robotics gearboxes

We believe in: Innovation is our soul and spirit. Excellent is our life. Buyer want is our God for OEM Customized 1module 20teeth with 1module 60 Teeth 1: 3 Speed Ratio Precision Spiral Bevel Gear 45 Steel Hardened 90 Degree Pinion, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

OEM Customized 1: 3 and Spiral Bevel Gear, Our company has already have pass the ITAF ISO standard and we are fully respect our customer ‘s patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.