Online Exporter Gear Spiral Bevel - Spiral Gear For High Precision Speed Reducer – Belon Detail:

The characteristics of spiral gears ?

Spiral bevel gears are divided into two types, one is a spiral bevel gear, whose large axle and small axle intersect; the other is a hypoid spiral bevel gear, with a certain offset distance between the large axle and the small axle. Spiral bevel gears are widely used in mechanical transmission fields such as automobiles, aviation, and mining due to their advantages such as large overlap coefficient, strong carrying capacity, large transmission ratio, smooth transmission, and low noise. Its characteristics are :

1. Straight bevel gear: The tooth line is a straight line, intersecting at the apex of the cone, shrinking the tooth.

2. Helical bevel gear: The tooth line is a straight line and is tangent to a point, shrinking the tooth.

3. Spiral bevel gears: retractable gears (also suitable for gears of equal height).

4. Cycloid spiral bevel gear: contour teeth.

5. Zero-degree spiral bevel gear: Double reduction teeth, βm=0, used to replace straight bevel gears, with better stability, but not as good as spiral bevel gears.

6. Cycloid-tooth zero-degree bevel gear: Contour teeth, βm=0, used to replace straight bevel gears, with better stability, but not as good as spiral bevel gears.

7. The tooth height types of spiral bevel gears are mainly divided into reduced teeth and equal height teeth. The reduced teeth include non-equal head clearance reduced teeth, equal head clearance reduced teeth and double reduced teeth.

8. Contour teeth: the teeth of the big end and the small end are of the same height, generally used for oscillating bevel gears.

9. Non-isotopic space shrinking teeth: the apexes of the sub-cone, the top cone and the root cone are coincident.

Manufacturing Plant

Production Process

Raw Material

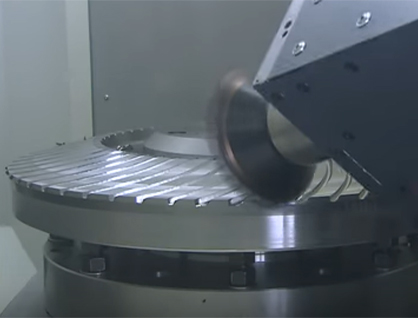

Rough Cutting

Turning

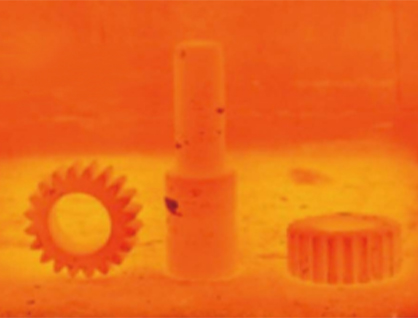

Quenching And Tempering

Gear Milling

Heat Treat

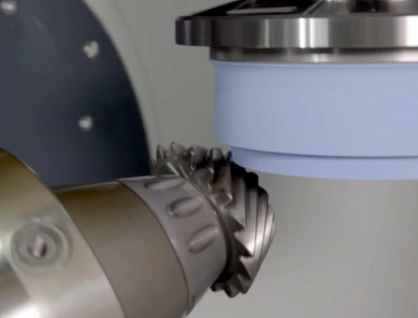

Gear Grinding

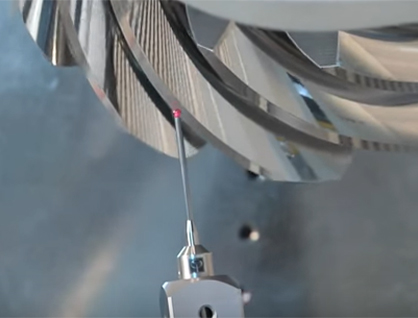

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Lapping Bevel Gear Or Grinding Bevel Gears

Spiral Bevel Gears

Bevel Gear Lapping Vs Bevel Gear Grinding

Bevel Gear Broaching

Spiral Bevel Gear Milling

Industrial Robot Spiral Bevel Gear Milling Method

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Online Exporter Gear Spiral Bevel - Spiral Gear For High Precision Speed Reducer – Belon , The product will supply to all over the world, such as: Sevilla, Barcelona, Rwanda, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.