One of the key advantages of planetary gear sets is their ability to distribute the load across multiple gears, resulting in increased durability and improved performance. This design also provides a high torque-to-weight ratio, making it ideal for applications that require powerful output in a compact form. Additionally, planetary gear systems offer versatility with different gear ratios, allowing for smooth

In industries like automotive and industrial machinery, planetary gear sets are commonly used in transmissions to provide multiple speeds and handle heavy loads. Their efficiency and durability make them a preferred choice for engineers looking to achieve precise motion control and power management. For those seeking reliability and performance, planetary gear systems

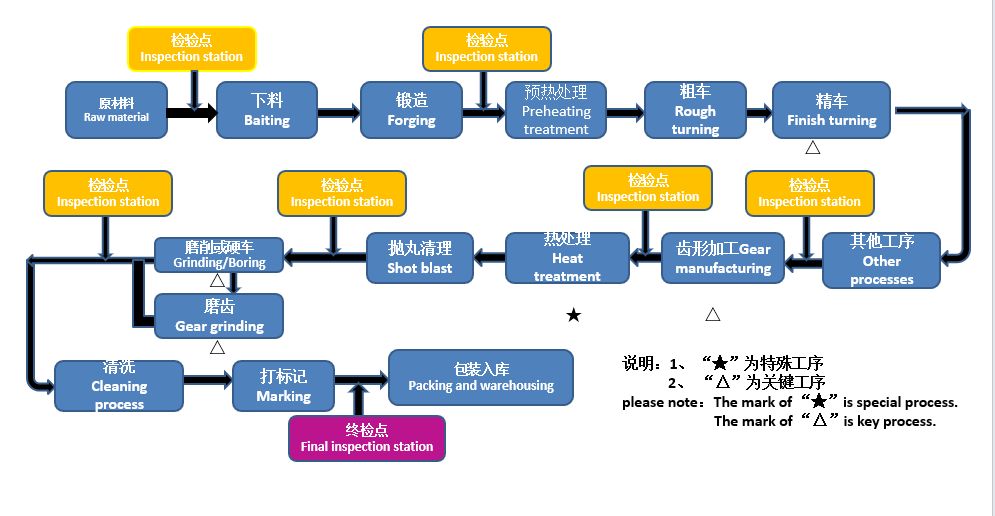

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Reports