Precision Alloy Steel Spur Motorcycle Gear Set Wheel

Upgrade your motorcycle’s performance with our Precision Alloy Steel Spur Gear Set Wheel. Engineered for durability and efficiency, this high quality gear set is crafted from premium alloy steel, ensuring exceptional strength, wear resistance, and longevity.

High-Strength Alloy Steel – Manufactured from top grade alloy steel, offering superior durability and resistance to wear.

Precision Machining – CNC-machined for accurate tooth profiles and smooth engagement, reducing noise and improving transmission efficiency.

Optimized Power Transmission – Designed for high torque capacity and seamless power transfer, enhancing overall motorcycle performance.

Heat Treated for Longevity – Advanced heat treatment technology ensures improved hardness, wear resistance, and extended lifespan.

Perfect Fit & Compatibility – Engineered to OEM specifications for a precise fit, making installation easy and reliable.

Whether you're upgrading your motorcycle’s transmission or replacing worn-out gears, this spur gear set wheel delivers the performance, strength, and efficiency needed for a smooth and powerful ride. Perfect for high-performance motorcycles, racing bikes, and daily commuters.

Inspection

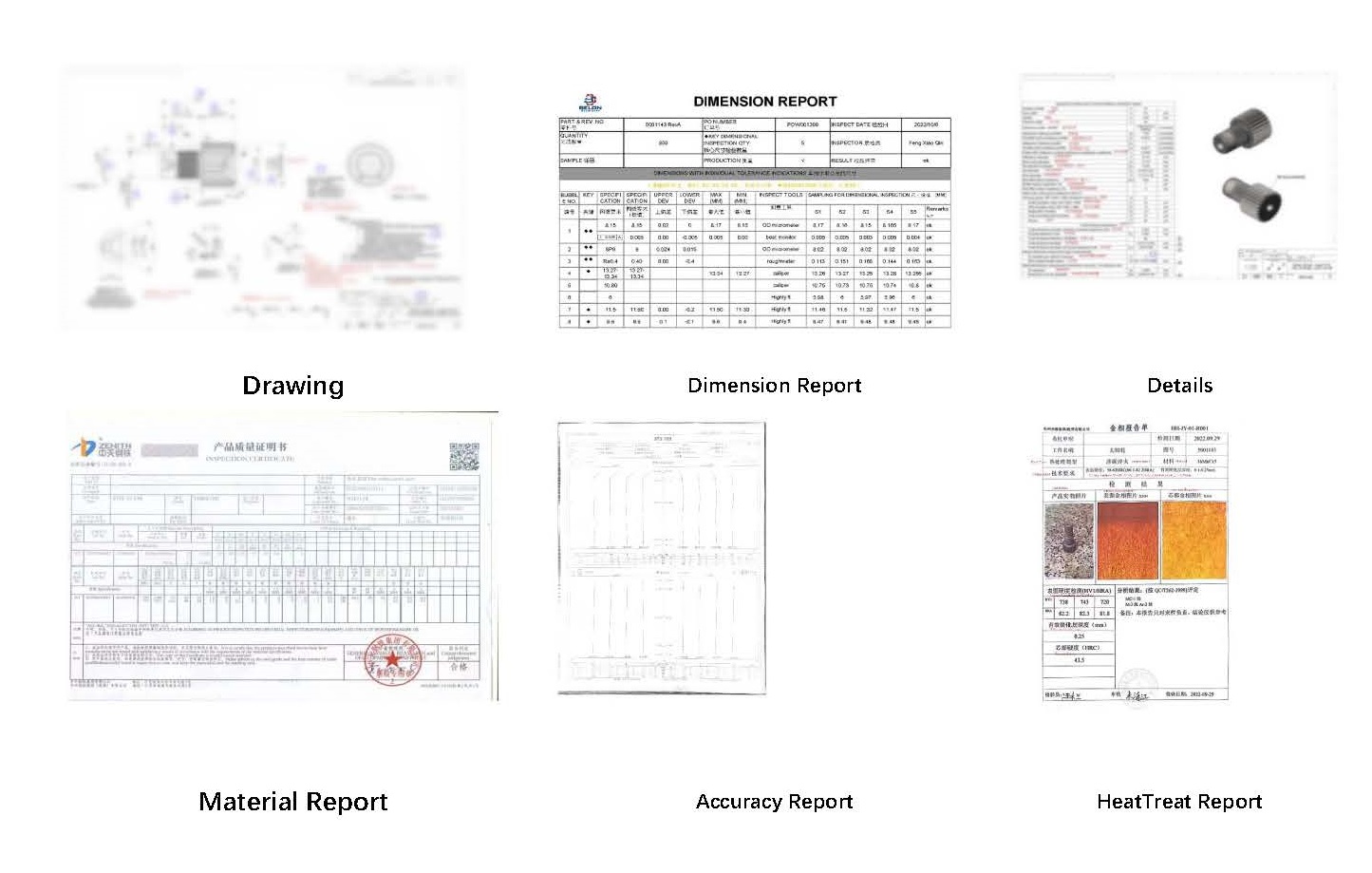

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Reports