Our straight-bevel gears increase efficiency and enhance power transfer to ensure every unit of energy is utilized efficiently. This results in superior performance and reduced energy waste, making it ideal for applications requiring peak efficiency. Our products are engineered to minimize friction, ensuring smooth, friction free operation, helping to extend system life and minimize drag, thereby increasing overall efficiency.

Each unit is crafted with extreme precision using cutting-edge forging technology, ensuring a flawless, uniform product that meets the highest industry standards. Precision engineered tooth profiles reflect our pursuit of excellence, promoting efficient power transmission while minimizing wear and noise, significantly increasing product life and reliability.

Straight Bevel Gear Application Suitable for industries ranging from automotive to industrial machinery, our right bevel configurations meet different needs. Its precision and reliability make it indispensable for seamless performance in a variety of applications. From heavy equipment to complex machinery in the industrial machinery sector, our right bevel configurations excel in ensuring precision and optimal performance.

The company has introduced Gleason Phoenix 600HC and 1000HC gear milling machines, which can process Gleason shrink teeth, Klingberg and other high gears; and Phoenix 600HG gear grinding machine, 800HG gear grinding machine, 600HTL gear grinding machine, 1000GMM, 1500GMM gear The detector can do closed-loop production, improve the processing speed and quality of products, shorten the processing cycle, and achieve fast delivery.

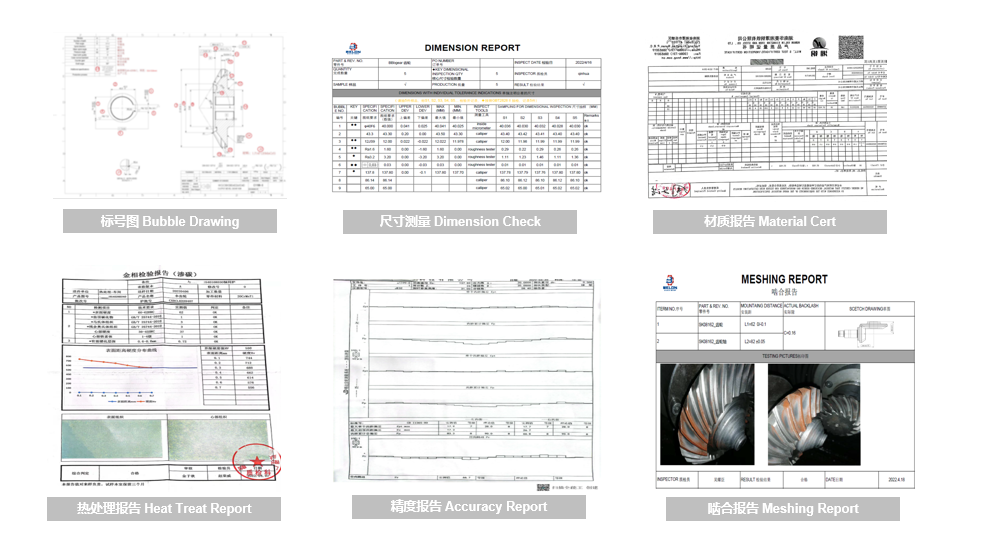

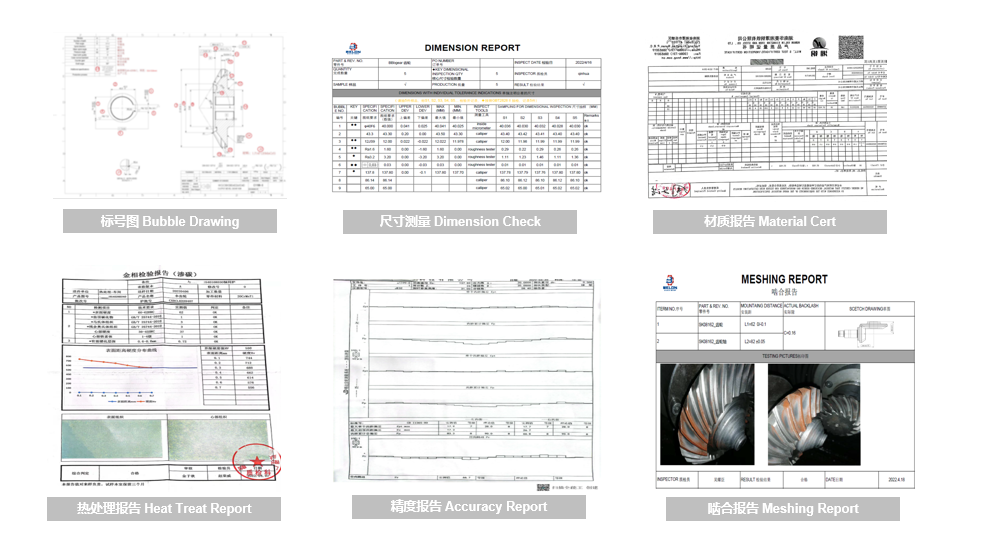

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1)Bubble drawing

2)Dimension report

3)Material cert

4)Heat treat report

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

7)Meshing test report