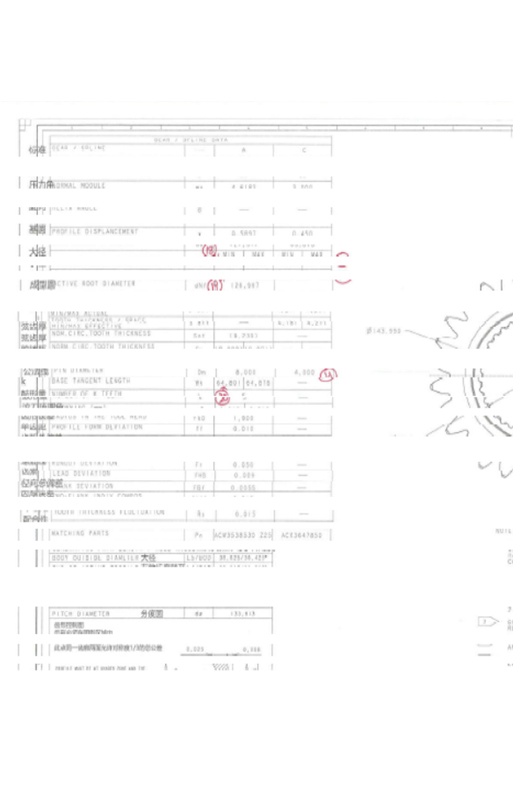

The spline shaft is divided into two types:

1) rectangular spline shaft

2) involute spline shaft.

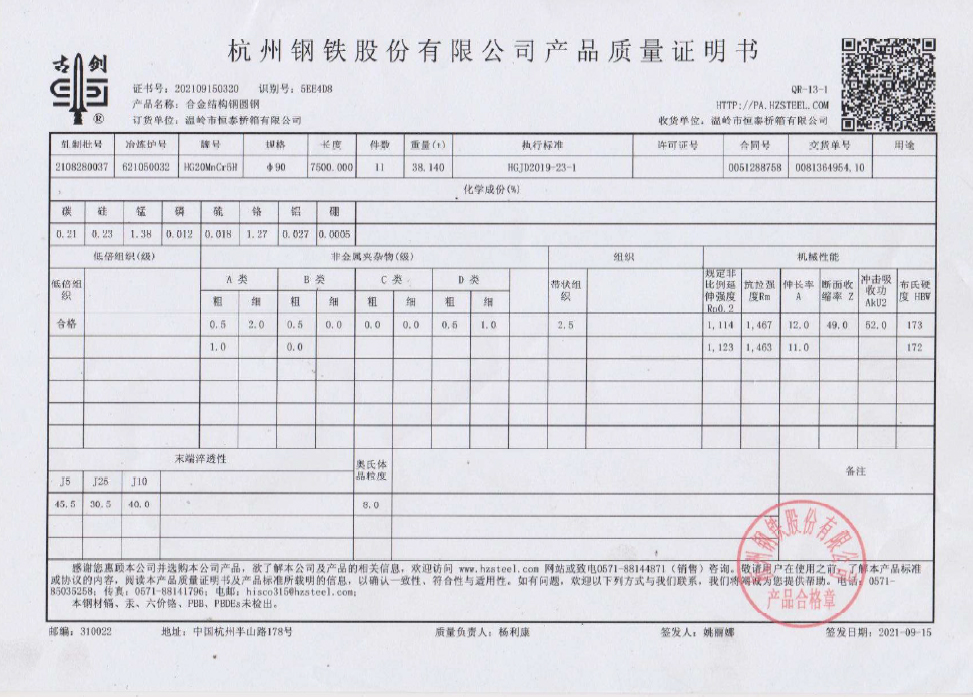

The rectangular spline shaft in the spline shaft is widely used, while the involute spline shaft is used for large loads and requires high centering accuracy. and larger connections. Rectangular spline shafts are usually used in aircraft, automobiles, tractors, machine tool manufacturing, agricultural machinery and general mechanical transmission devices. Due to the multi-tooth operation of the rectangular spline shaft, it has high bearing capacity, good neutrality and good guidance, and its shallow tooth root can make its stress concentration small. In addition, the strength of the shaft and the hub of the spline shaft is less weakened, the processing is more convenient, and higher precision can be obtained by grinding.

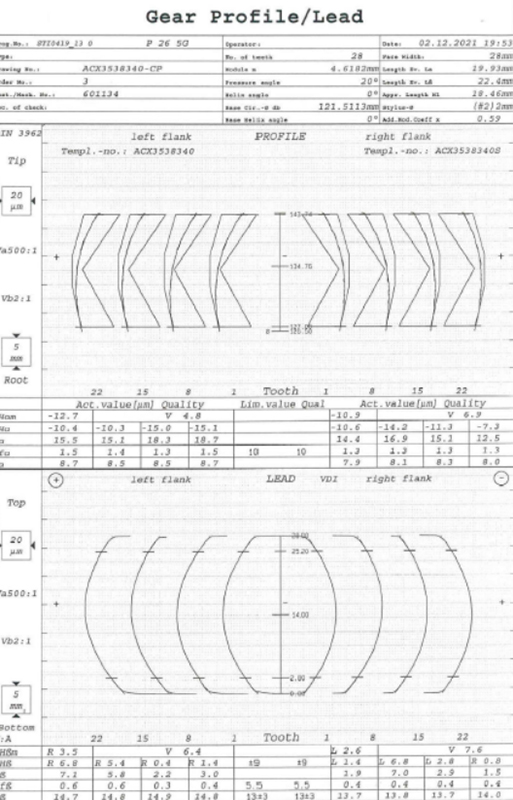

Involute spline shafts are used for connections with high loads, high centering accuracy, and large dimensions. Its characteristics: the tooth profile is involute, and there is radial force on the tooth when it is loaded, which can play the role of automatic centering, so that the force on each tooth is uniform, high strength and long life, the processing technology is the same as that of the gear, and it is easy to obtain high precision and interchangeability