Customized factory design precision drive spline shaft and gear shaft for agricultural industrial machine tools

Spline shafts play a crucial role in agricultural machinery, enabling the smooth and efficient transfer of power between different components. These shafts have a series of grooves or splines that interlock with corresponding grooves in mating parts, ensuring secure torque transmission without slippage. This design allows for both rotational movement and axial sliding, making spline shafts ideal for the heavy-duty demands of agricultural equipment.

One of the primary applications of spline shafts in agriculture is in Power Take-Off (PTO) systems. PTO shafts are used to transmit power from the tractor to various implements such as mowers, balers, and tillers. The splined connection allows for precise alignment, robust power transfer, and the ability to withstand high loads and stress, ensuring durability in harsh working conditions

Processing hot/cold forging, heat treatment, cnc turning, milling, drilling and tapping, surface treatment, laser cutting, stamping, die casting

Materials available costomized aluminum, copper, brass, stainless steel,carbon steel alloy steel

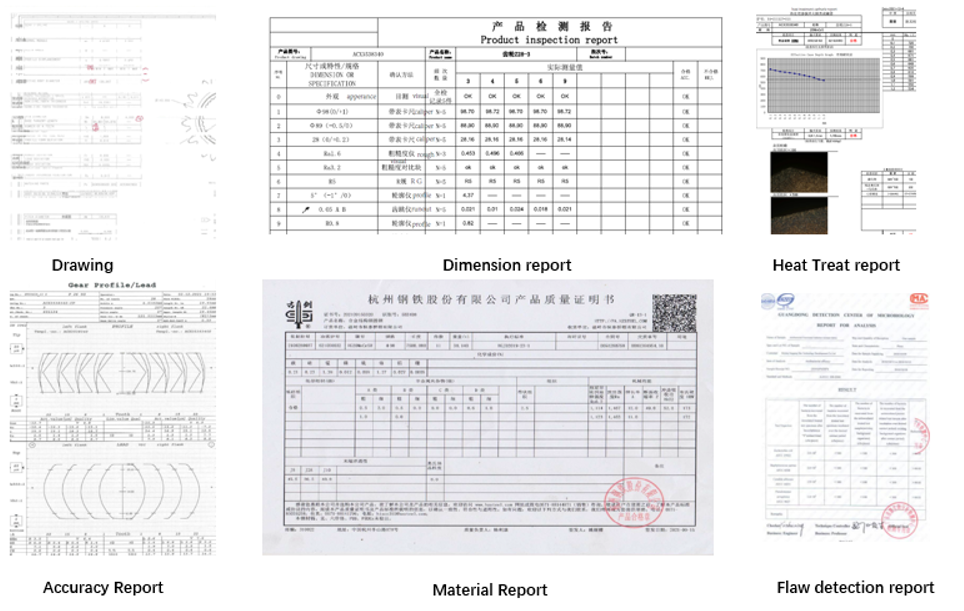

Inspection

Reports