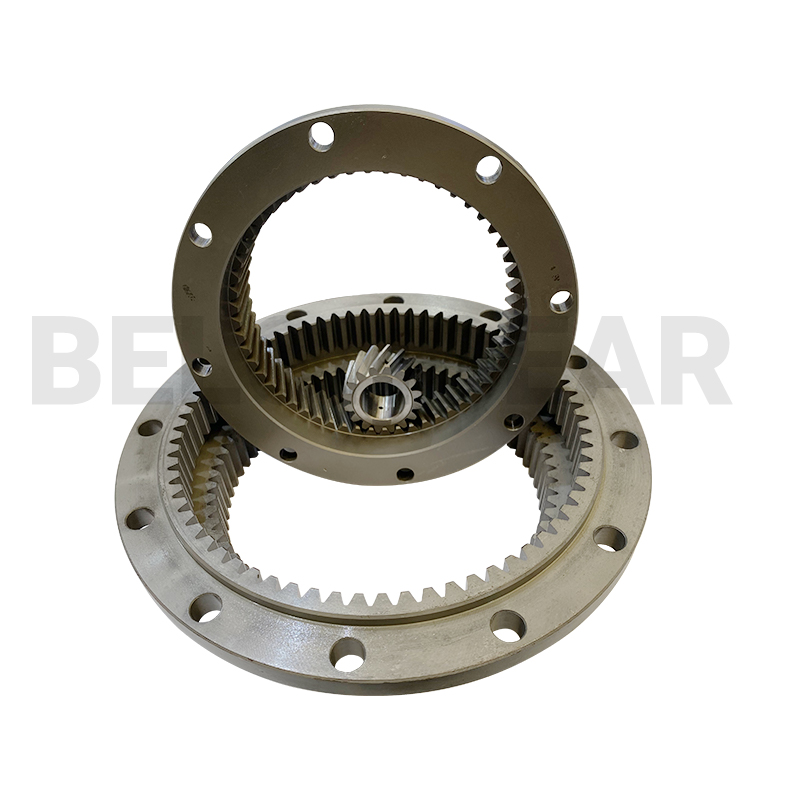

Professional China Straight Spur Gear - Internal Spur Gear And Helical Gear For Planetary Speed Reducer – Belon Detail:

Features

Planetary speed reducer used in large and medium-sized construction machinery has many characteristics compared with other types of gearbox, such as compact structure, high transmission efficiency, small between tooth load, stiffness big, easy to realize power shift transmission, etc. This kind of gearbox consists of several basic planetary row by fitting the transmission speed reducer, rely on shift gear shifting clutch and brake control component.

Application

The planetary reduction mechanism is used in the transmission part of low speed and high torque, especially in the side drive of construction machinery and the rotating part of tower crane.This kind of planetary reduction mechanism requires flexible rotation and strong transmission torque capacity.

Planetary gears are gear parts widely used in planetary reduction. At present, the requirements for the planetary gears to be processed are very high, the requirements for gear noise are high, and the gears are required to be clean and free of burrs. The first is the material requirements; the second is that the tooth profile of the gear meets the DIN3962-8 standard, and the tooth profile must not be concave , third, the roundness error and cylindricity error of the gear after grinding are high, and the inner hole surface .There are high roughness requirements. Technical requirements for gears

Manufacturing Plant

Production Process

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Internal Gear Shapping

How To Test Internal Ring Gear And Make The Accurancy Report

How Internal Gears Produced To Speed Up Delivery

Internal Gear Grinding And Inspection

Internal Gear Shapping

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Professional China Straight Spur Gear - Internal Spur Gear And Helical Gear For Planetary Speed Reducer – Belon , The product will supply to all over the world, such as: Russia, Tunisia, Brunei, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!