Spiral Gear Bevel Gearing for Spiral Gearbox

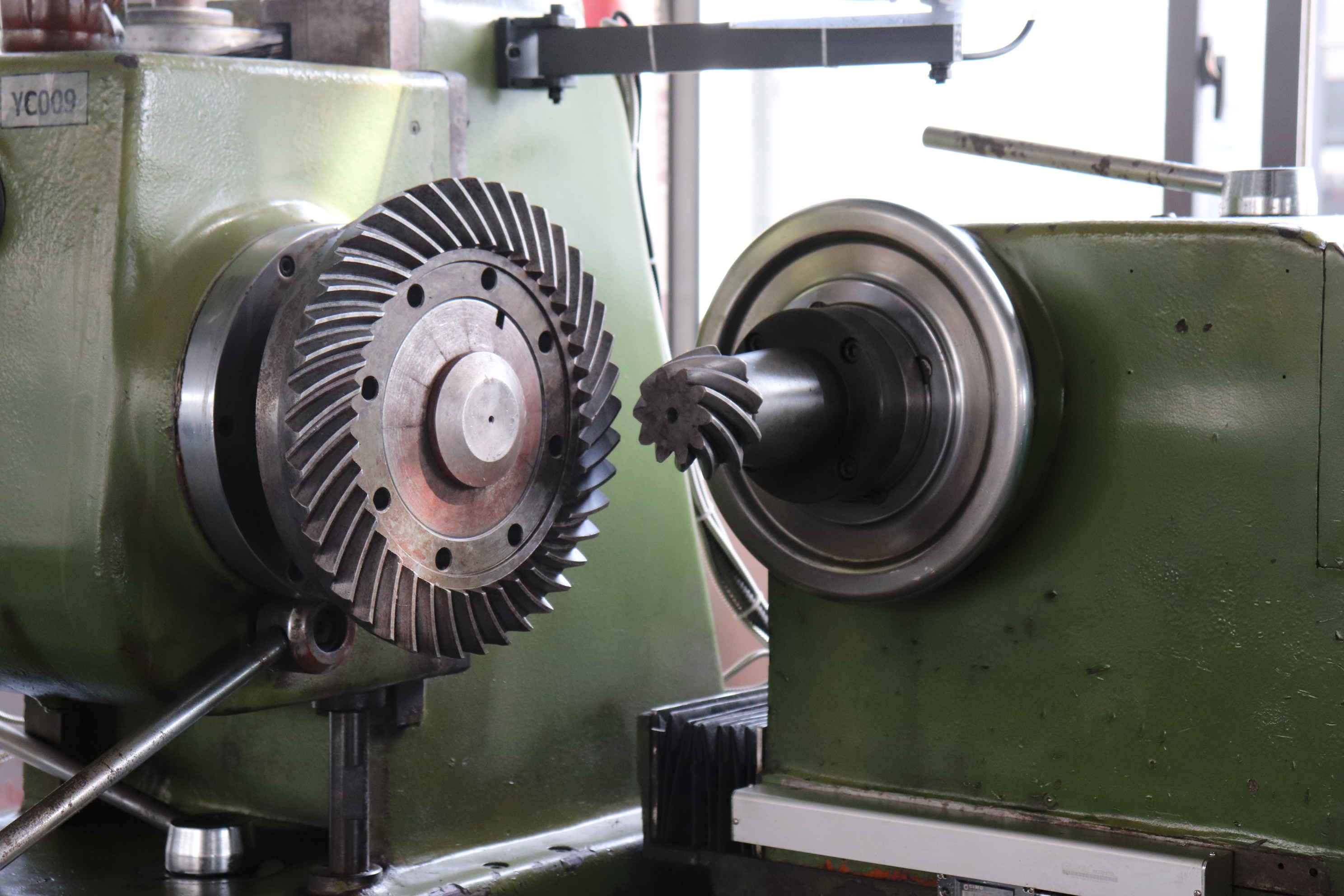

Spiral gear bevel gearing is a crucial component in the design of spiral gearboxes, offering high efficiency and smooth power transmission. These gears are characterized by their curved teeth, which engage gradually, reducing noise and vibration compared to straight bevel gears. This feature makes them ideal for applications requiring precision and durability, such as automotive differentials, industrial machinery, and aerospace systems.

The spiral gear's unique design ensures better contact between gear teeth, distributing the load evenly and enhancing torque capacity. This results in longer operational life and reduced wear, even under high-speed or high-load conditions. Spiral gear bevel gearing is also known for its compact design, making it suitable for space constrained environments.

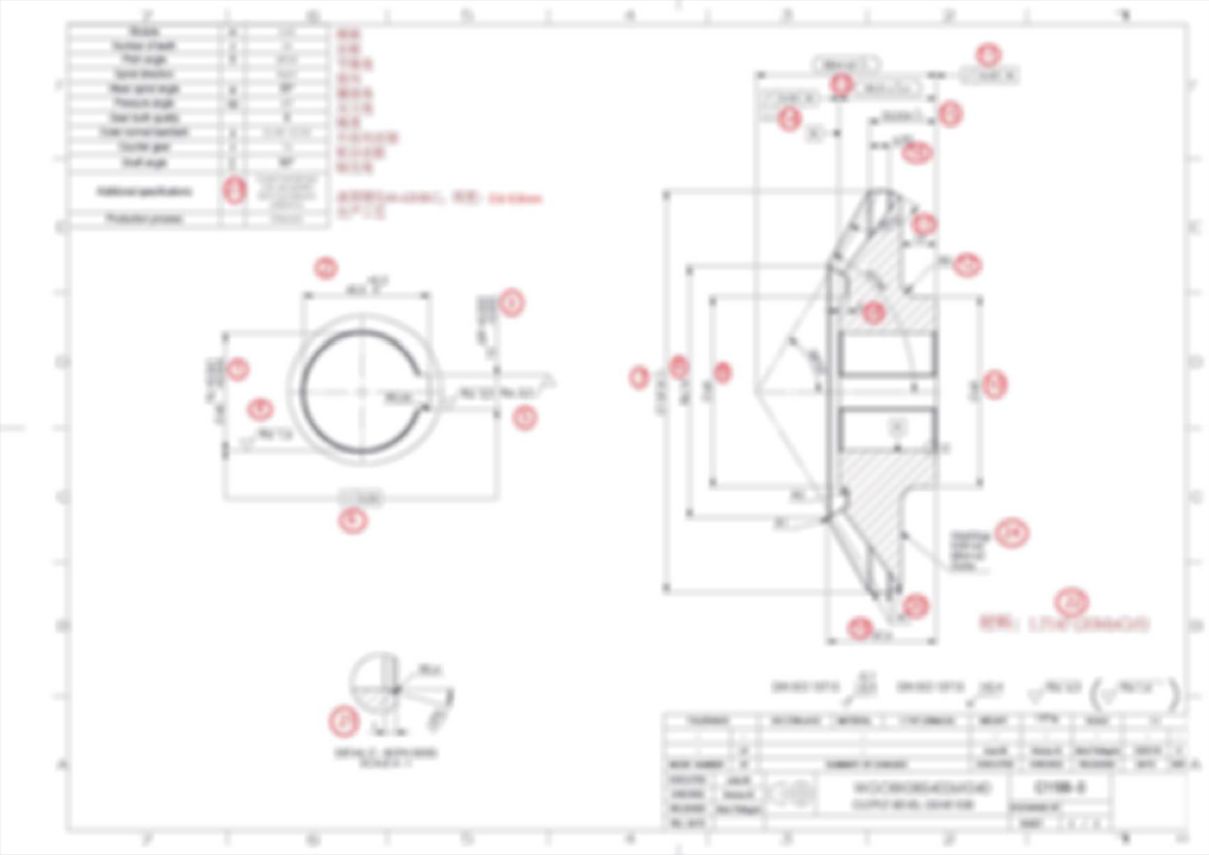

When choosing spiral gear bevel gearing for a spiral gearbox, factors like material, surface treatment, and precision grade should be considered to ensure optimal performance. Investing in high-quality spiral gears can significantly improve system reliability and efficiency in demanding applications.

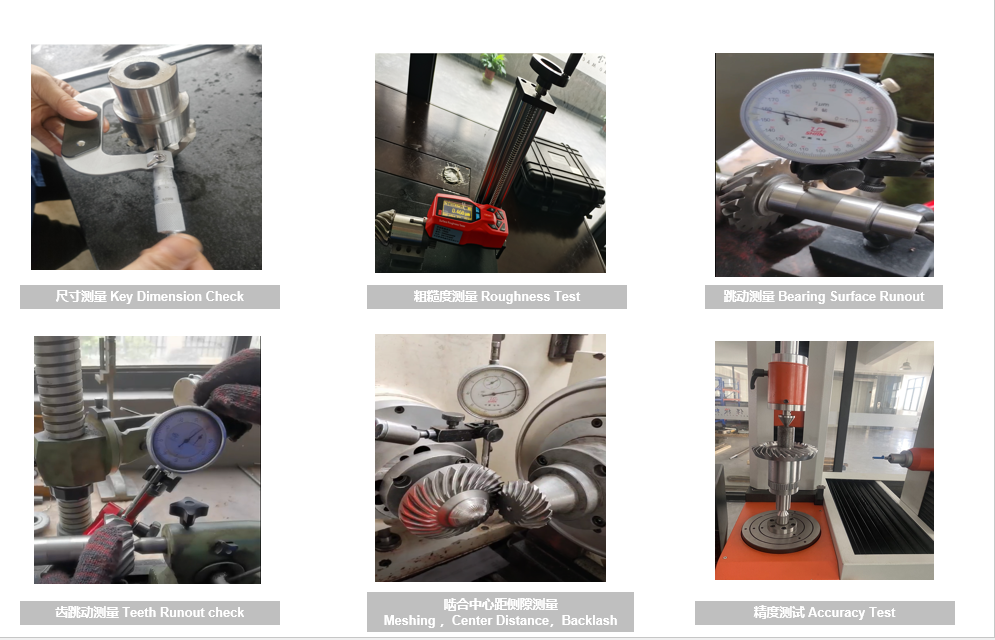

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1.Bubble drawing

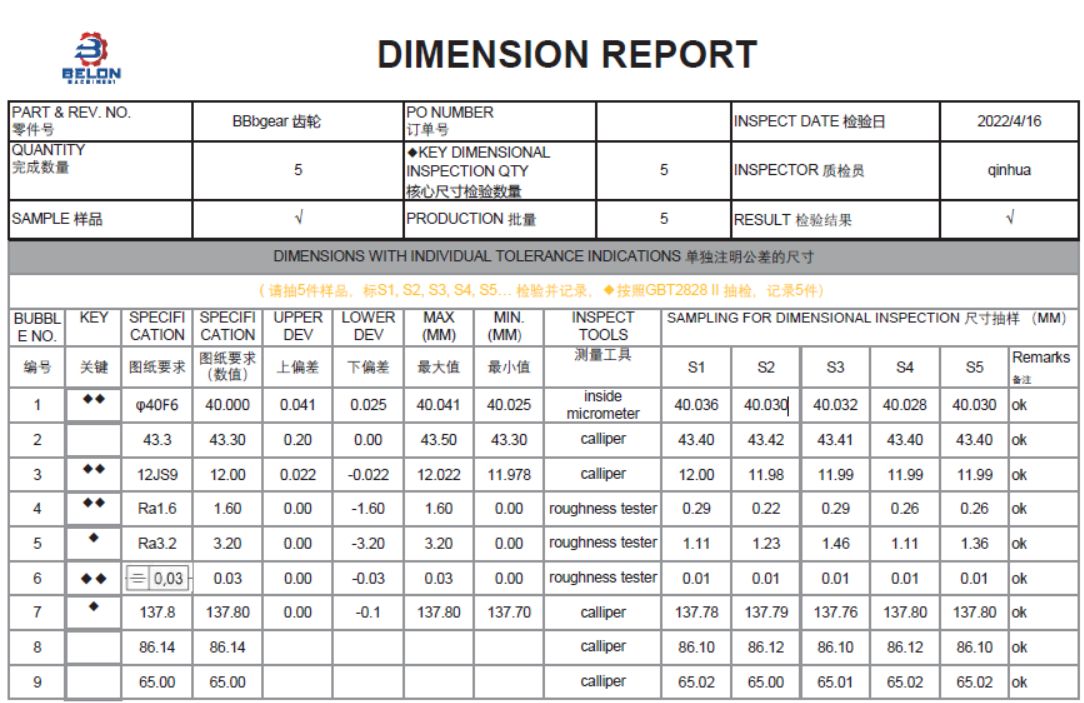

2.Dimension report

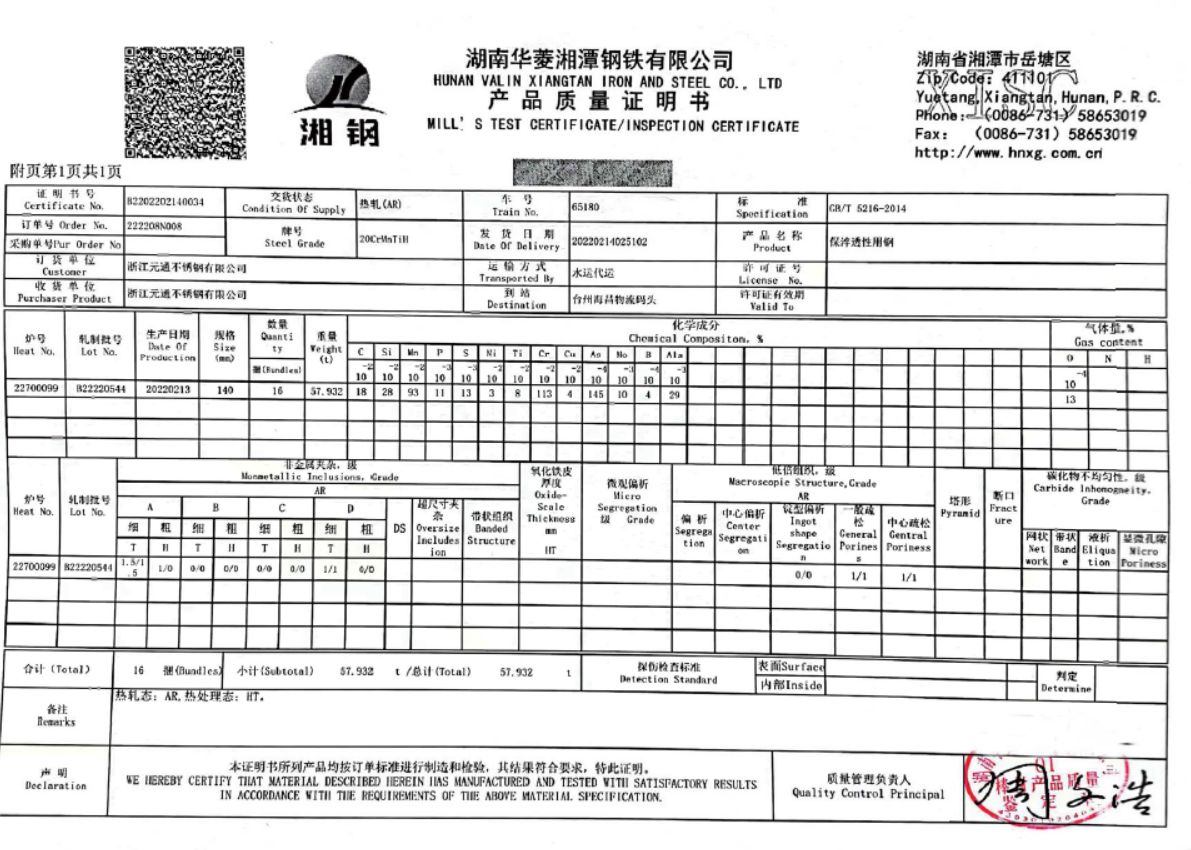

3.Material cert

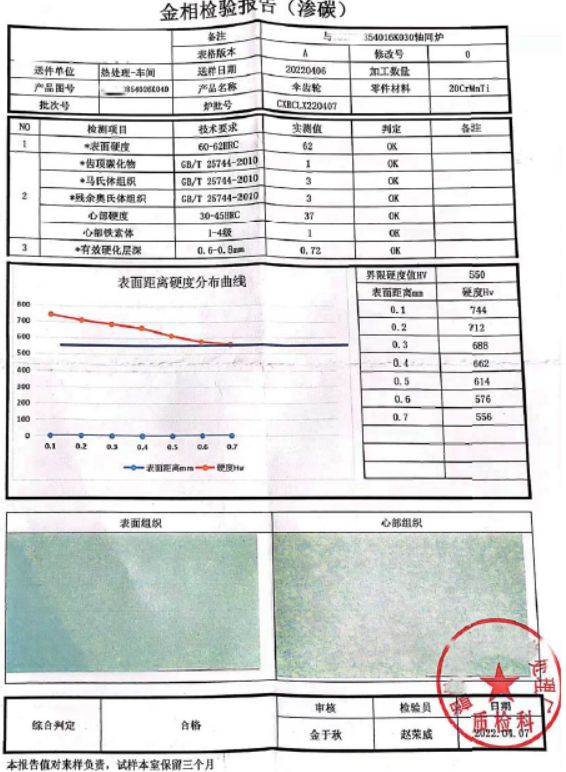

4.Heat treat report

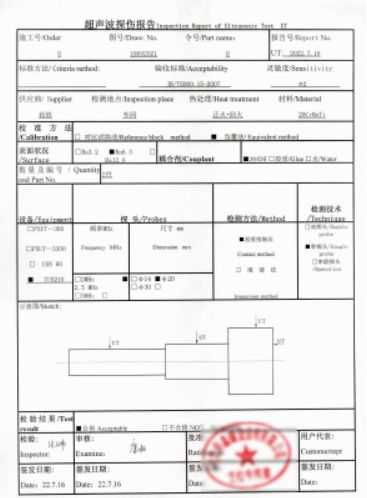

5.Ultrasonic Test report (UT)

6.Magnetic Particle Test report (MT)

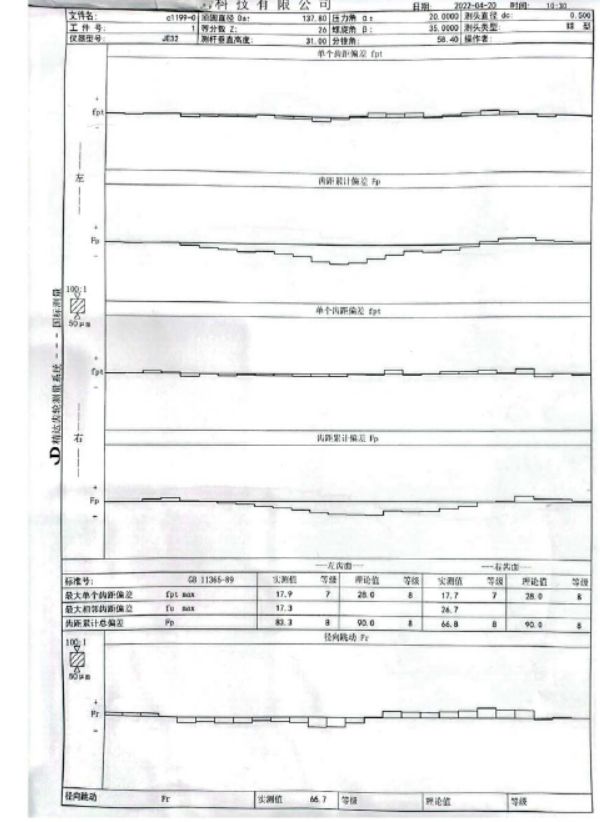

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of GearsTeeth

→ Highest accuracy DIN5-6

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

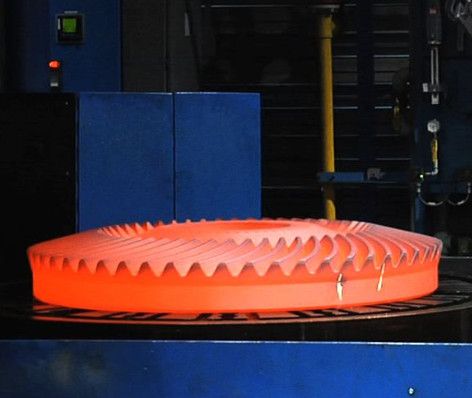

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

Lapping