Spiral Gears for Custom Machinery & Mechanical Equipment

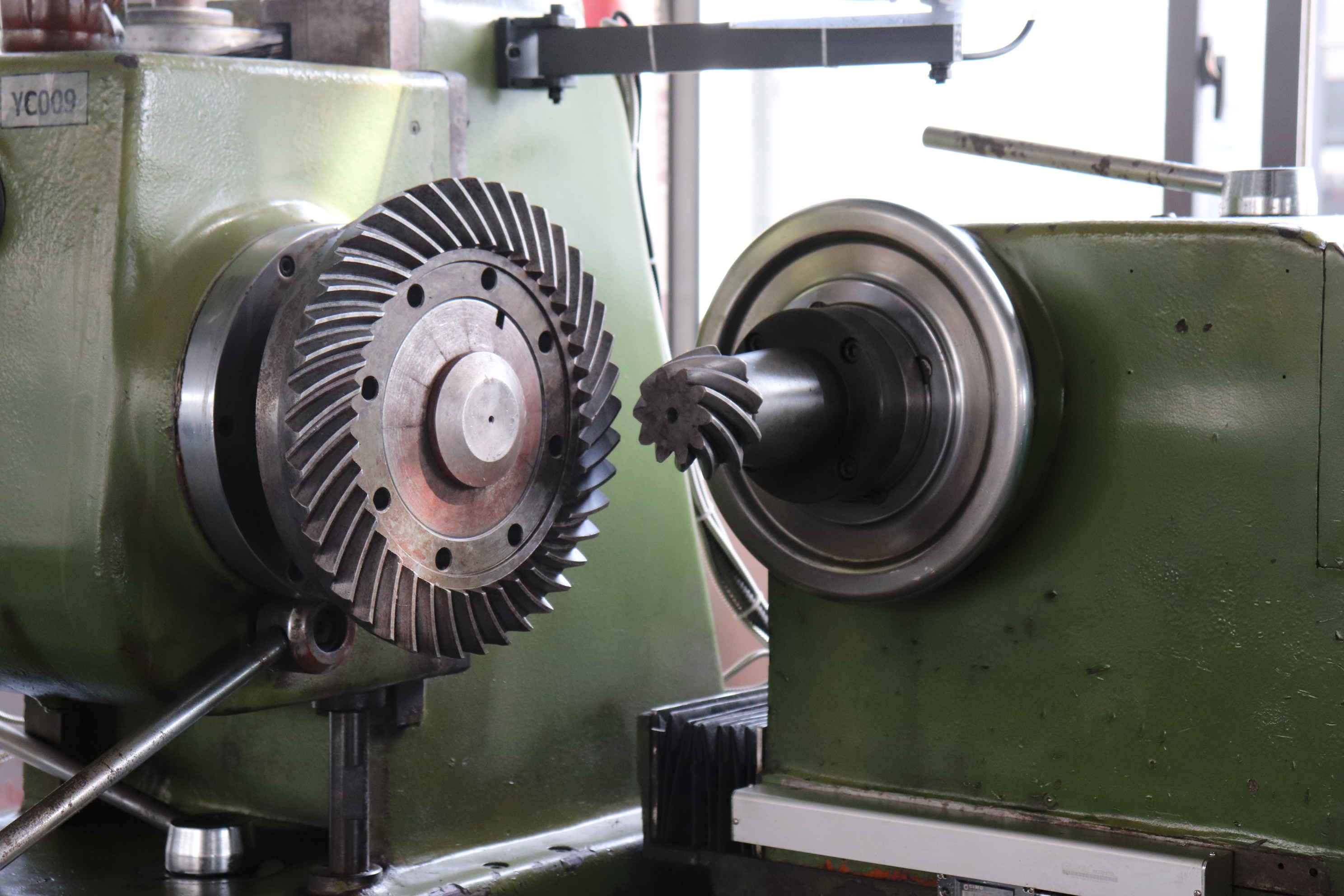

Spiral Gears are engineered to meet the demanding needs of custom machinery and mechanical equipment across various industries. Designed with precision and durability in mind, these gears ensure smooth power transmission, reduced noise levels, and enhanced operational efficiency.

Key Features:

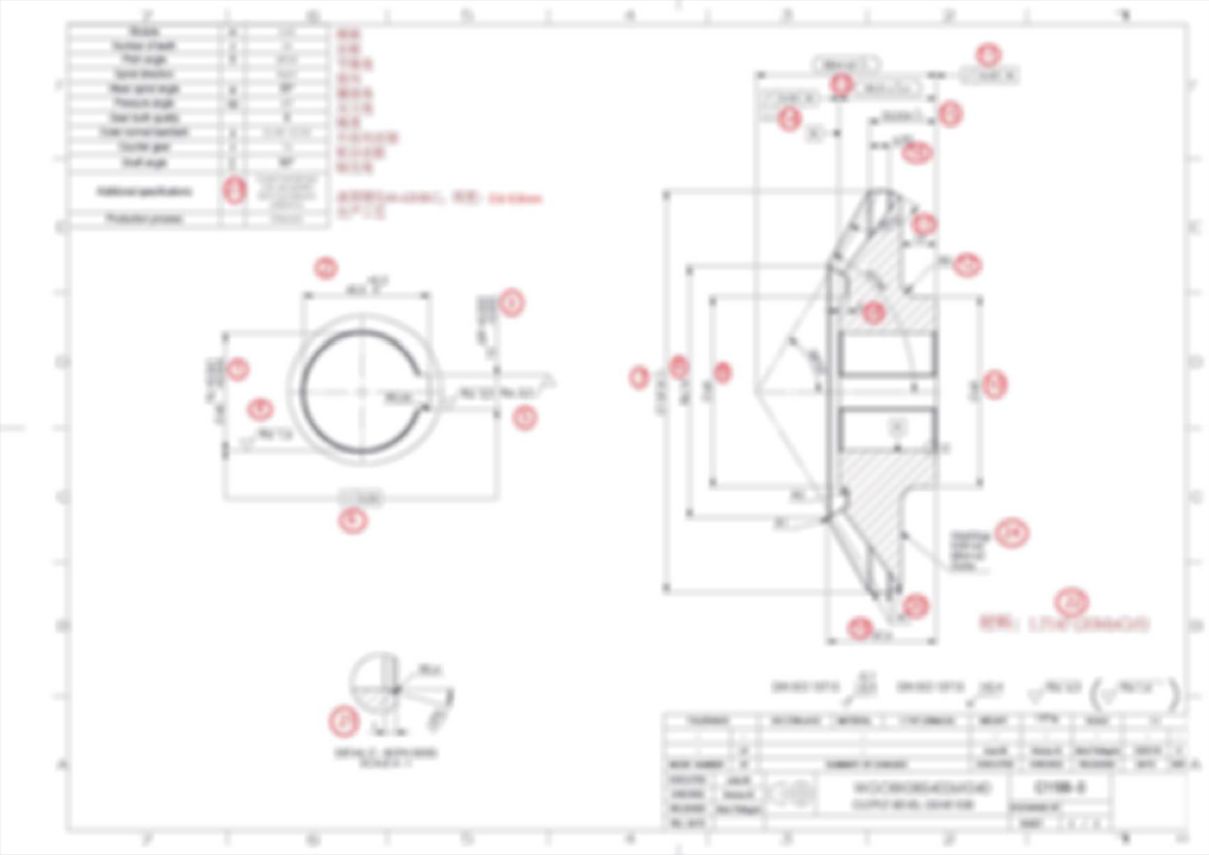

1. High Precision: Manufactured using advanced CNC machining and grinding techniques for superior accuracy.1.Customizable Designs: Tailored to fit specific machinery requirements, including unique dimensions, tooth profiles, and materials

2. Durable Materials: Available in high-strength steel, stainless steel, and other alloys for long-lasting performance.

3. Low Noise Operation: Optimized spiral bevel design minimizes vibration and noise, ideal for sensitive environments.

4. High Load Capacity: Built to handle heavy-duty applications and high-torque systems.

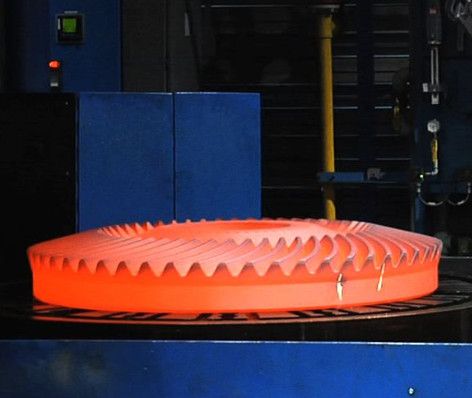

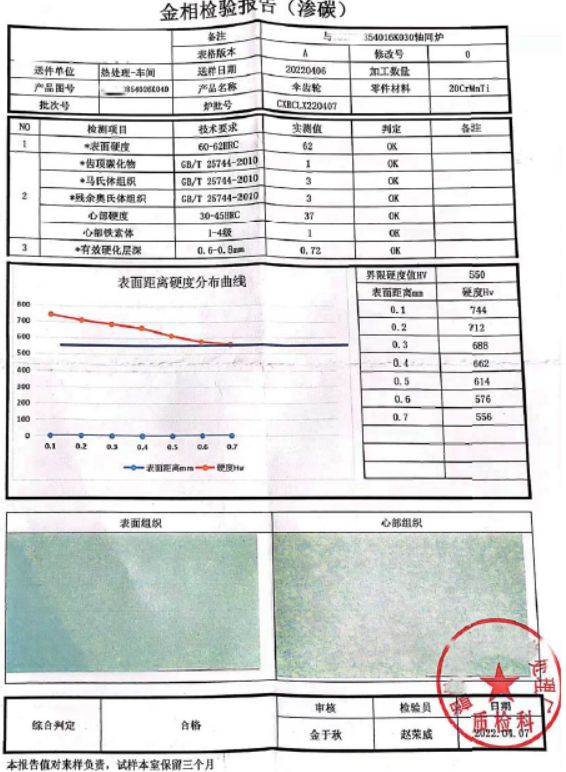

5. Heat Treatment: Enhanced surface hardness and wear resistance through advanced heat treatment processes.

Our products spiral bevel gears are widely used in various industrial fields, such as automotive, machinery manufacturing, engineering machinery, etc., to provide customers with reliable transmission solutions. We are committed to providing our customers with high-quality, high performance precision gear products to meet the needs of different applications. Choosing our products is a guarantee of reliability, durability, and superior performance.

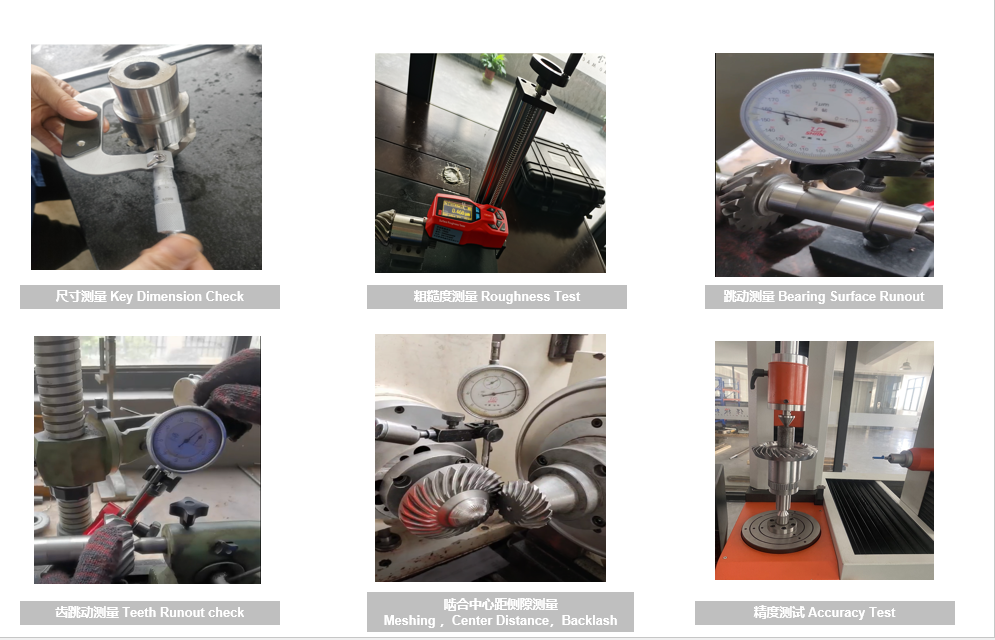

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1)Bubble drawing

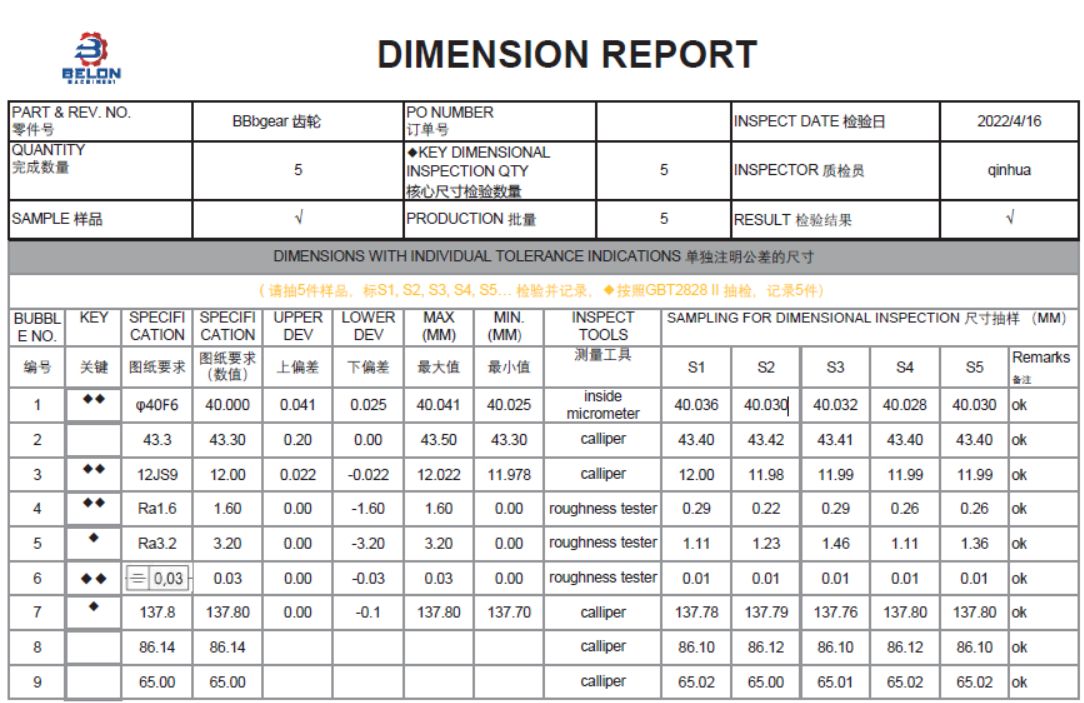

2)Dimension report

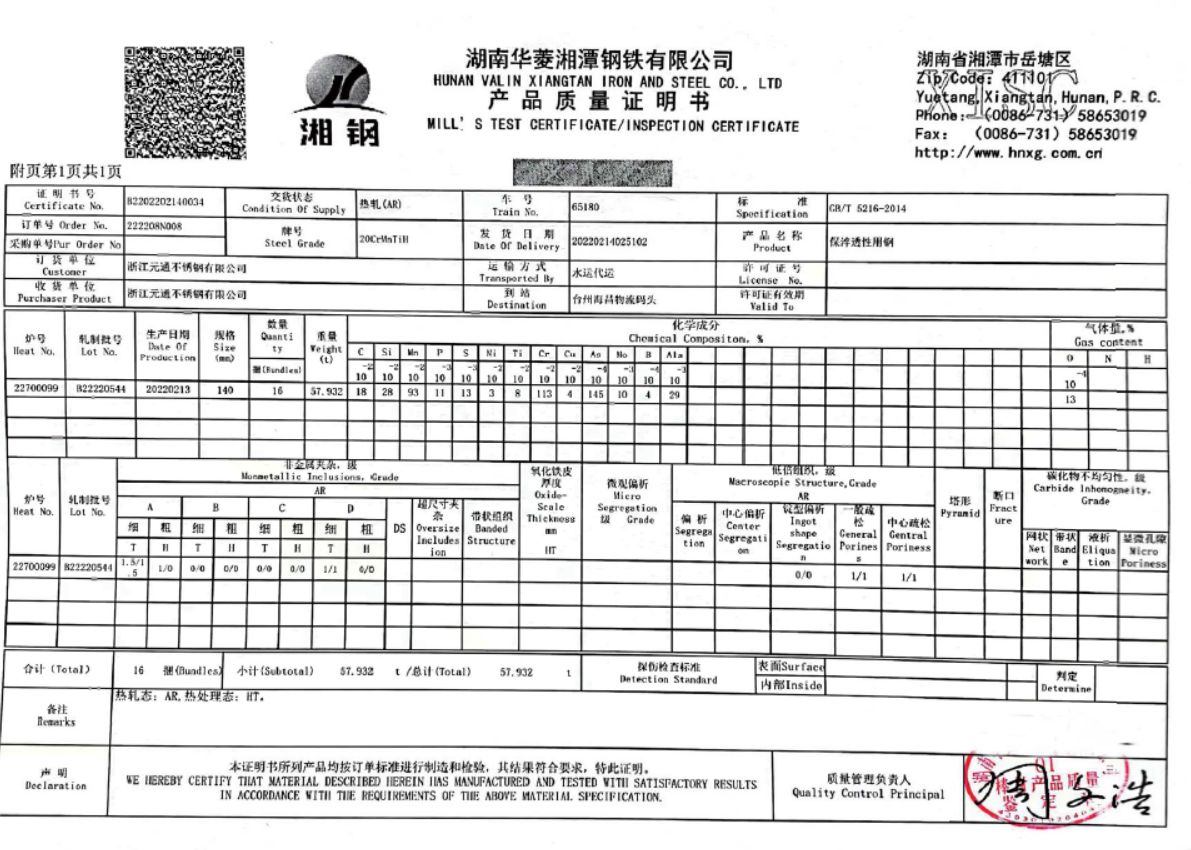

3)Material cert

4)Heat treat report

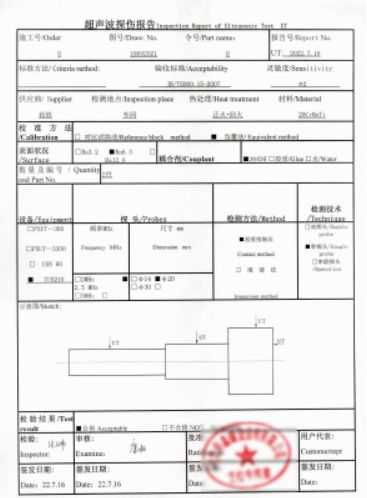

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

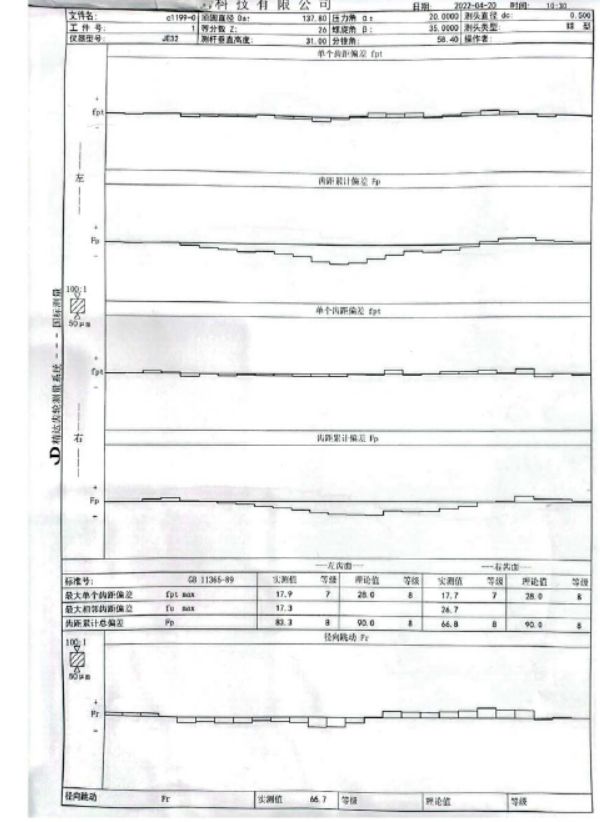

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

Lapping