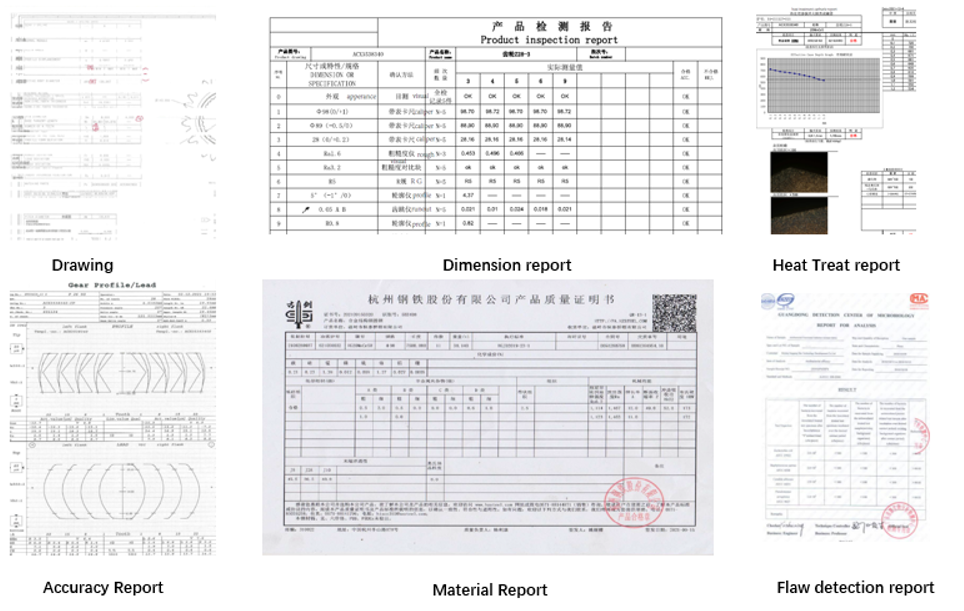

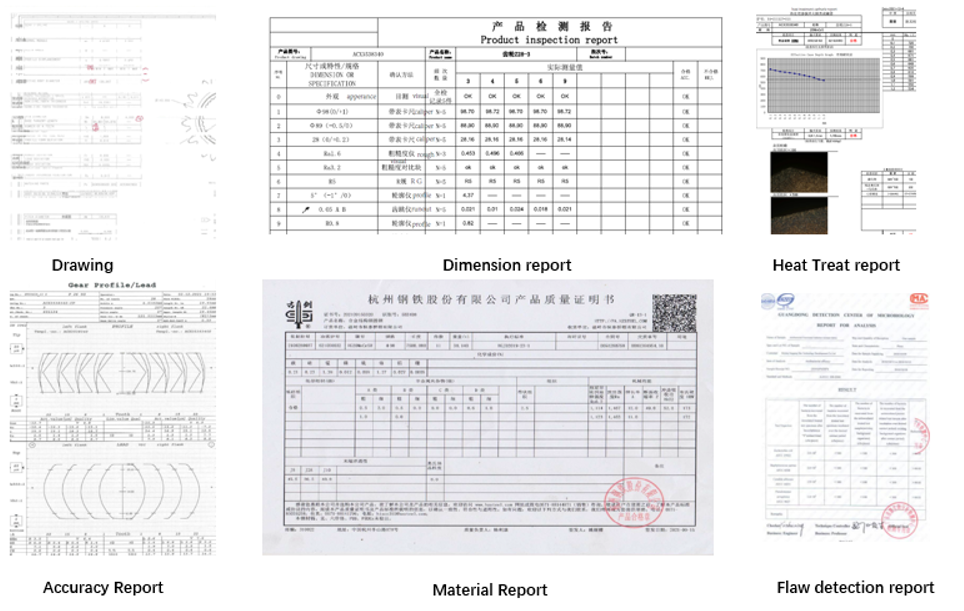

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .