The spur gear shaft is the most important supporting and rotating part in construction machinery, which can realize the rotary motion of gears and other components, and can transmit torque and power over a long distance. It has the advantages of high transmission efficiency, long service life and compact structure. It has been widely used and has become one of the basic parts of construction machinery transmission. At present, with the rapid development of the domestic economy and the expansion of infrastructure, there will be a new wave of demand for construction machinery. The material selection of the gear shaft, the way of heat treatment, the installation and adjustment of the machining fixture, the hobbing process parameters, and the feed are all very important to the processing quality and life of the gear shaft.

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Reports

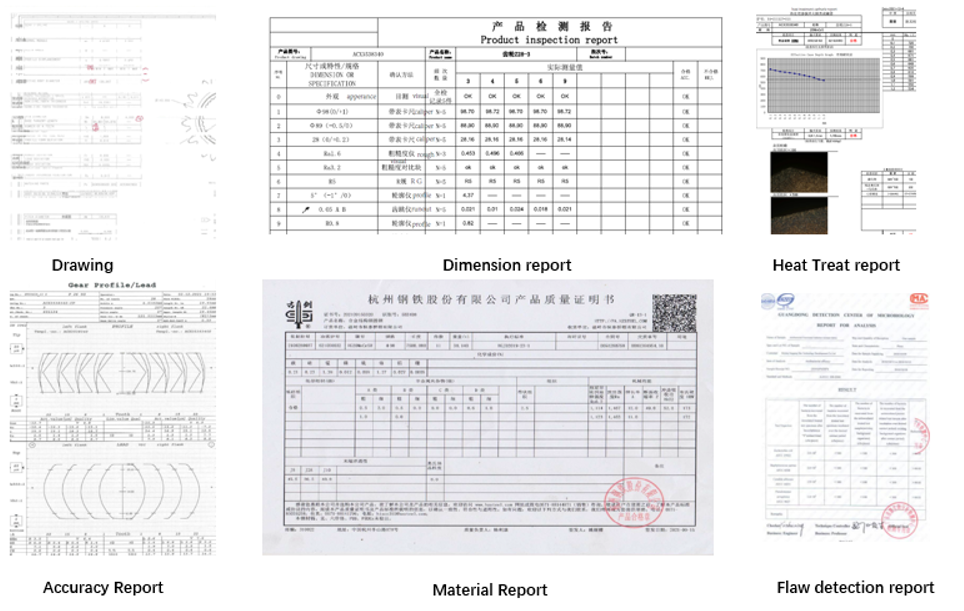

1).Bubble drawing

2).Dimension report

3).Material cert

4).Heat treat report

5).Accuracy report