Super Purchasing for Small Bevel Gears - DIN8 bevel gear and pinion in bevel helical gearmotors – Belon Detail:

Product details

These kinds of bevel gear and pinion are used at bevel helical gearmotor which are particularly suitable for conveyor applications. They offer great flexibility thanks to their solid and hollow output shaft options.

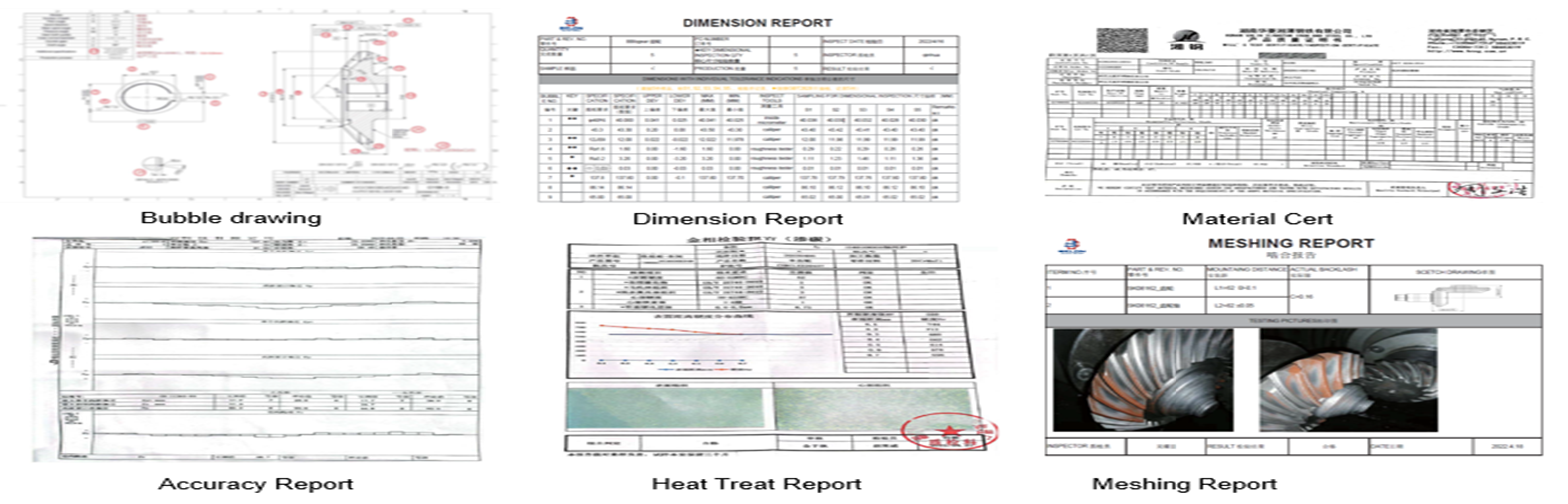

The important reports for such kinds of bevel gears are :

1) Dimension report (plus bearing surface runout testing video)

2) Material report before heat treat

3) Heat Treat report plus hardness and Metallographic

4) Accuracy test report

5) Meshing Test report (plus center distance ,backlash testing videos)

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

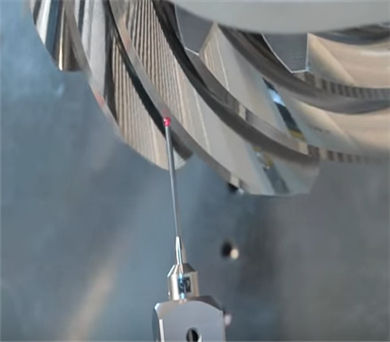

Gear Milling

Heat Treat

Gear Lapping

Testing

Inspection :

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Super Purchasing for Small Bevel Gears - DIN8 bevel gear and pinion in bevel helical gearmotors – Belon , The product will supply to all over the world, such as: Pakistan, Nigeria, California, Our tenet is "integrity first, quality best". Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.