The spline shaft is a kind of mechanical transmission. It has the same function as the flat key, the semicircular key and the oblique key. They all transmit mechanical torque. There are longitudinal keyways on the surface of the shaft. Rotate synchronously with the axis. While rotating, some can also slide longitudinally on the shaft, such as gearbox shifting gears

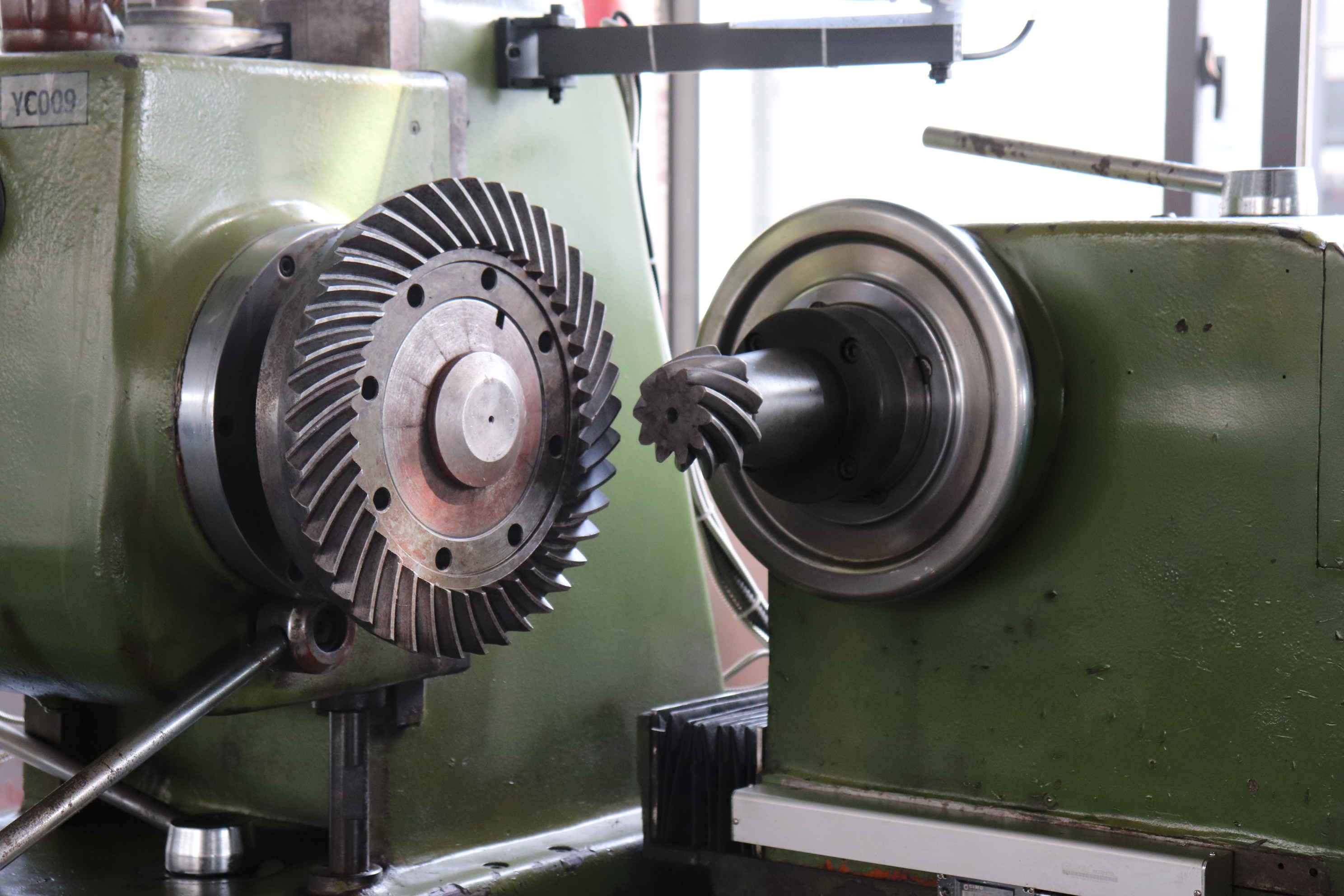

Here's how lapped bevel gears contribute to the performance of reducers :

Smooth Operation: Lapped bevel gears undergo a finishing process known as lapping, which results in a smoother tooth surface. This smoothness leads to a quieter operation and reduced noise during the meshing of gears in a reducer .

High Precision: The lapping process improves the precision of the gear teeth, which is essential for maintaining the accuracy and efficiency of the power transmission in reducers .

Material and Durability: Lapped bevel gears used in reducers are typically made from high-quality, case-hardened alloy steel. This material provides high strength and durability, which is necessary for the demanding conditions often encountered in agricultural machinery.

Efficiency: The manufacturing process of lapped bevel gears, including case-hardening, quenching, and lapping, ensures high efficiency in power transmission with minimal power loss

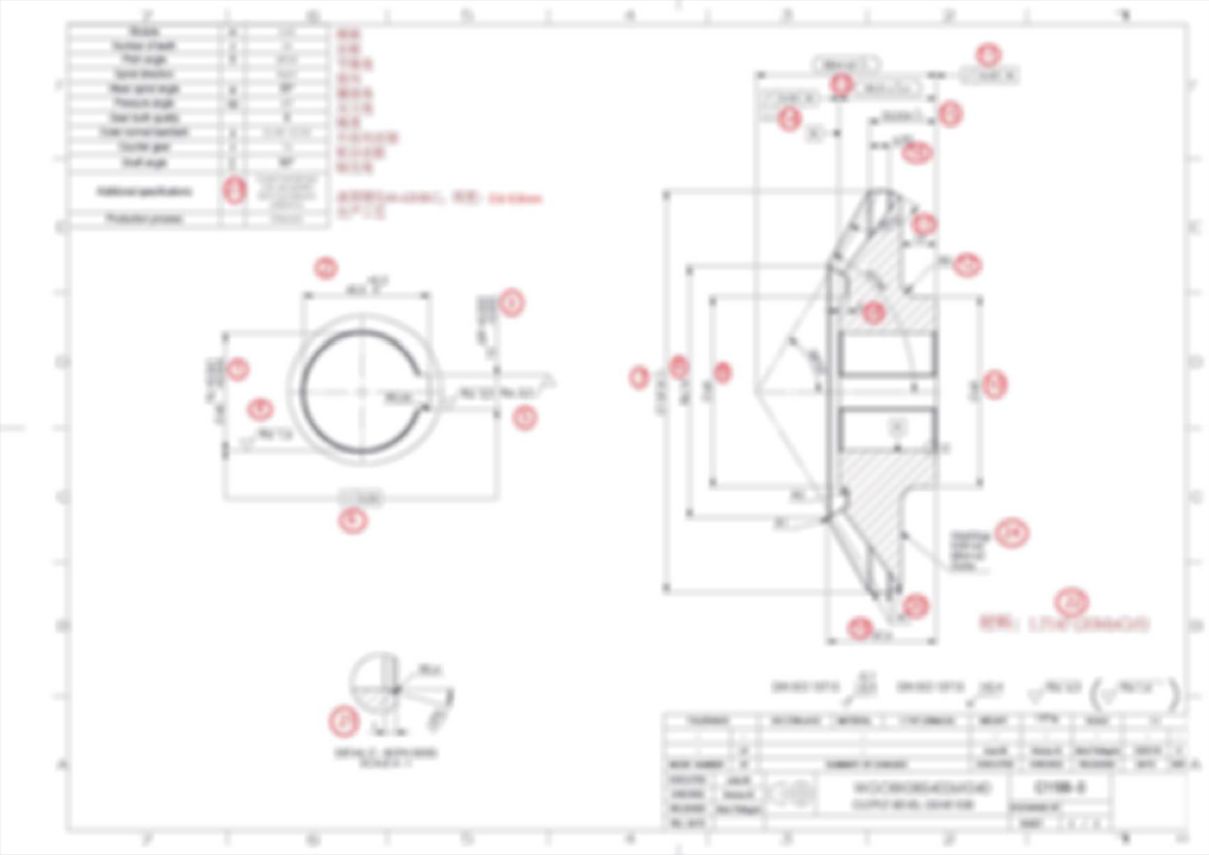

Customization: Lapped bevel gears can be customized to meet specific requirements for different types of reducers, including those used in specialized agricultural applications .

Long Service Life: The combination of high-quality materials and precise c

Versatility: Lapped bevel gears are suitable for use in various types of reducers, providing versatility in design and application. They can be used in both standard and high-performance applications, including those that require high input speeds and low noise levels.

Custom Bevel Gears Supplier ,Our products helical bevel gears are widely used in various industrial fields, such as automotive, machinery manufacturing, engineering machinery, etc., to provide customers with reliable transmission solutions. We are committed to providing our customers with high-quality, high-performance precision gear products to meet the needs of different applications. Choosing our products is a guarantee of reliability, durability, and superior performance.

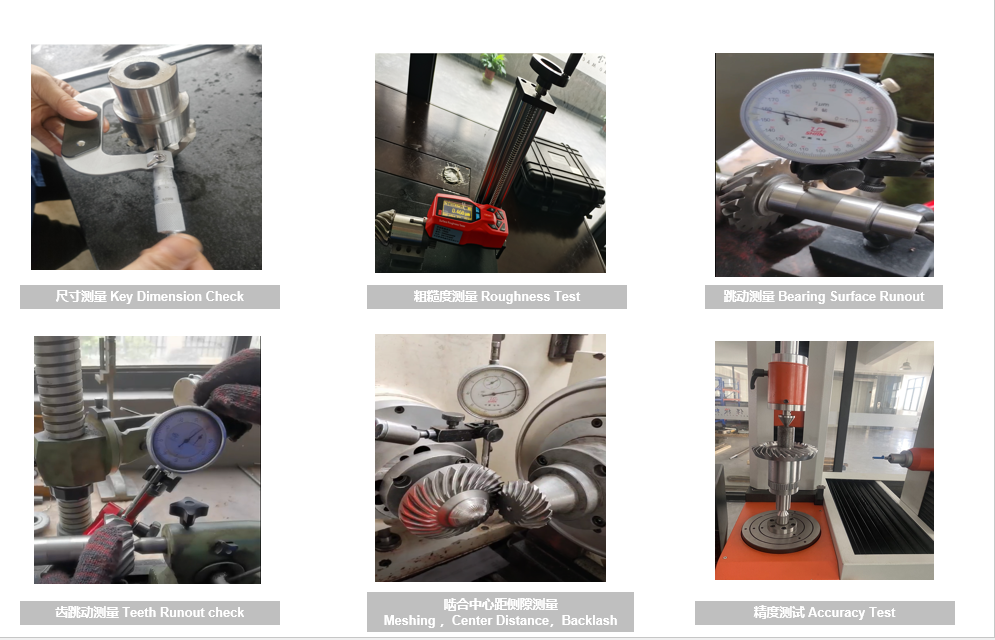

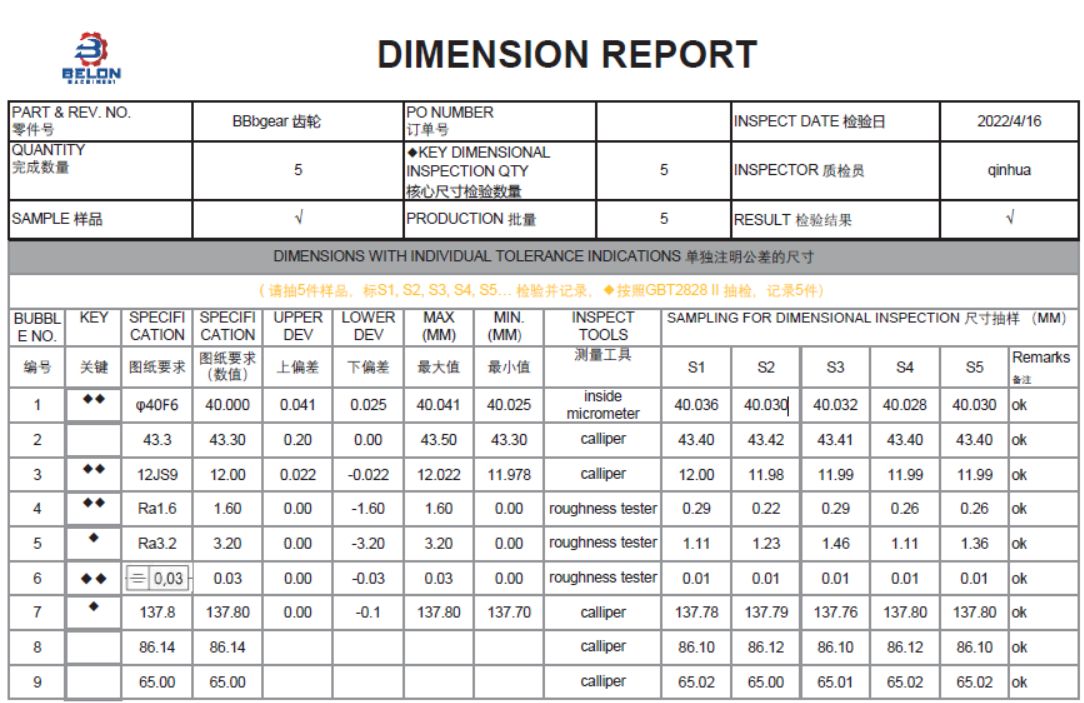

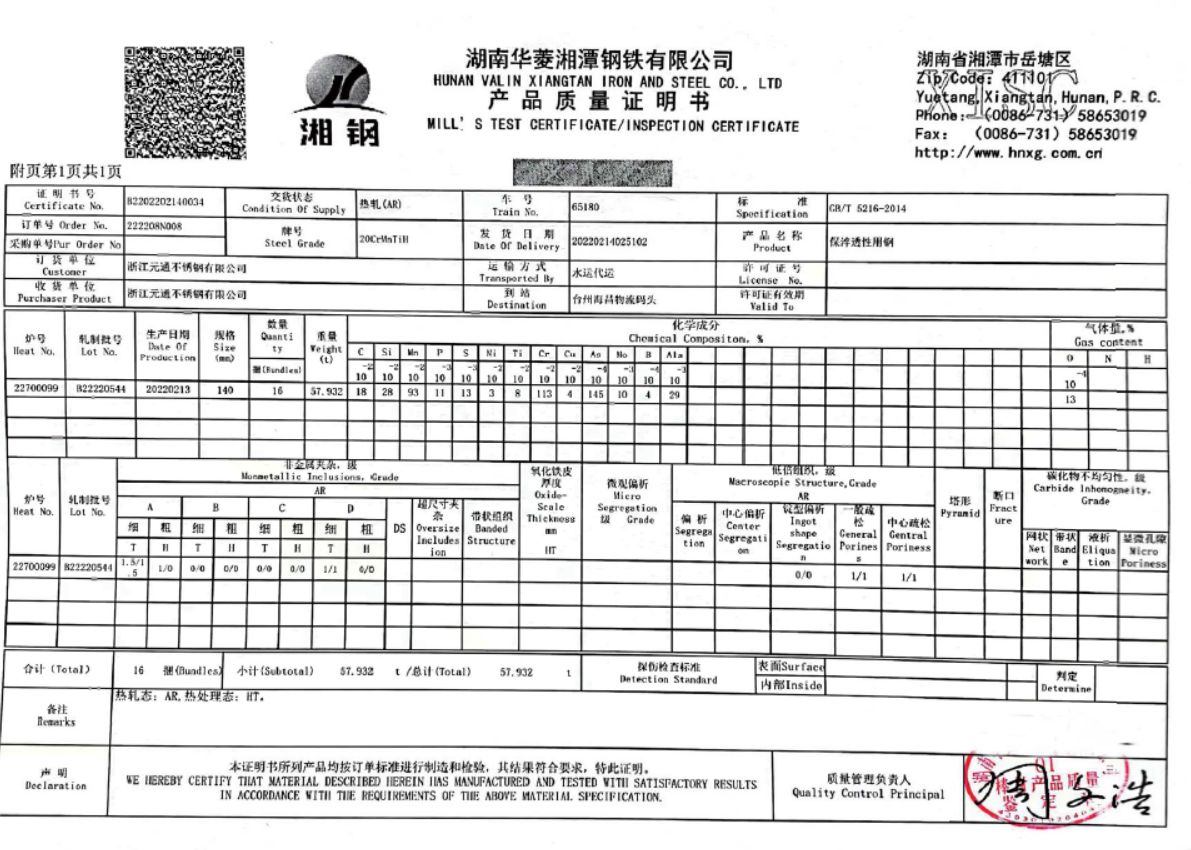

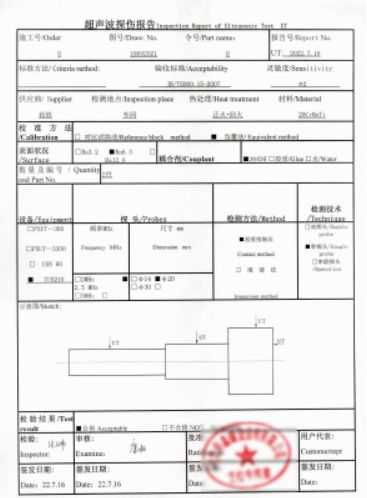

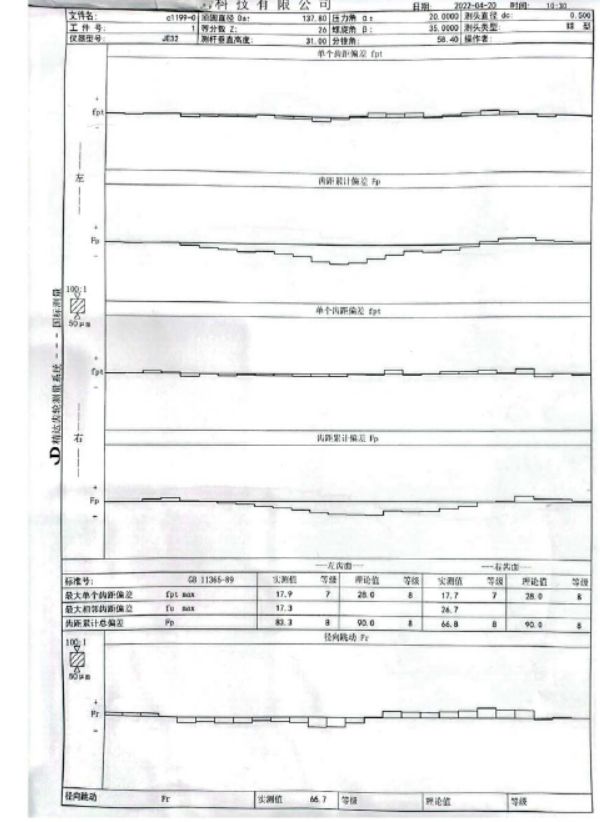

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1)Bubble drawing

2)Dimension report

3)Material cert

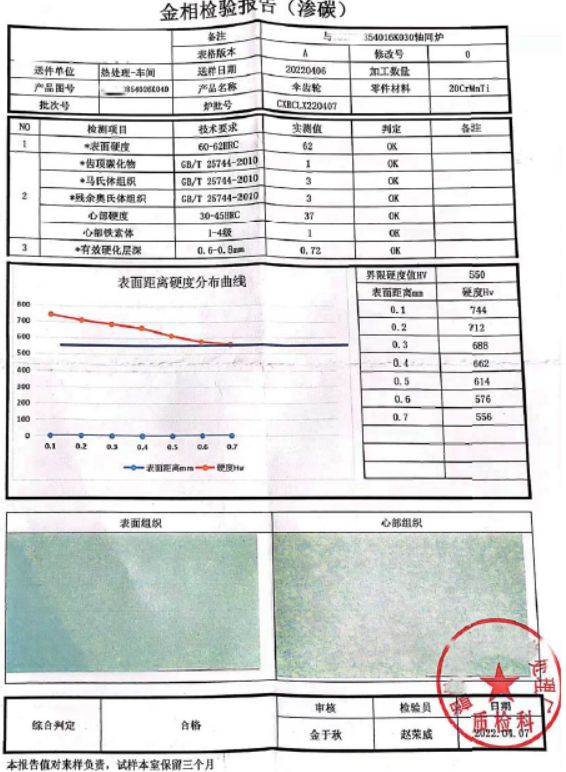

4)Heat treat report

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

Meshing test report ,Inspection bevel gears :Key Dimension Check、Roughness Test、Bearing Surface Runout 、Teeth Runout check,Meshing 、Center Distance, Backlash、Accuracy Test

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

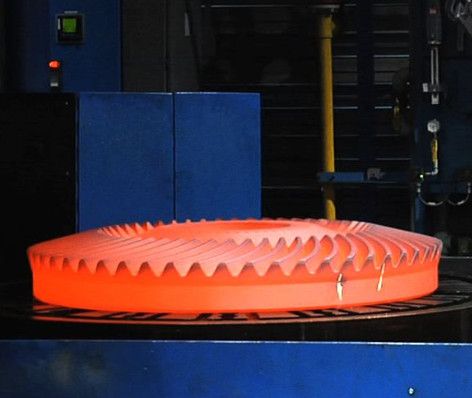

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

Lapping