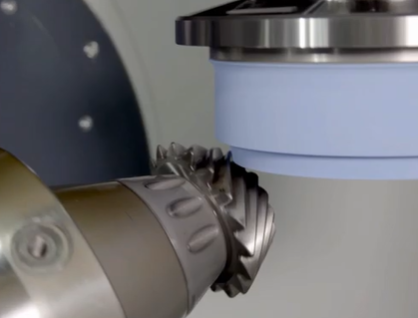

Manufacturers customize high precision OEM Sprial bevel gear for robot cnc lathes and automation equipment gear gearbox

Bevel gears for robots come in various sizes and configurations to fit a wide range of robotic systems, from small, precise assembly robots to large industrial automation machines.

These gears are designed to seamlessly integrate with robotic control systems, allowing for precise control and synchronization with other robotic components.

Manufacturers often provide customization options to meet the specific requirements of different robotic applications, including custom gear ratios, sizes, and materials.

Bevel gears are used in various robotic systems such as robotic arms for precise movements, automated guided vehicles (AGVs), and other automated machinery where motion control and torque transmission are required.

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

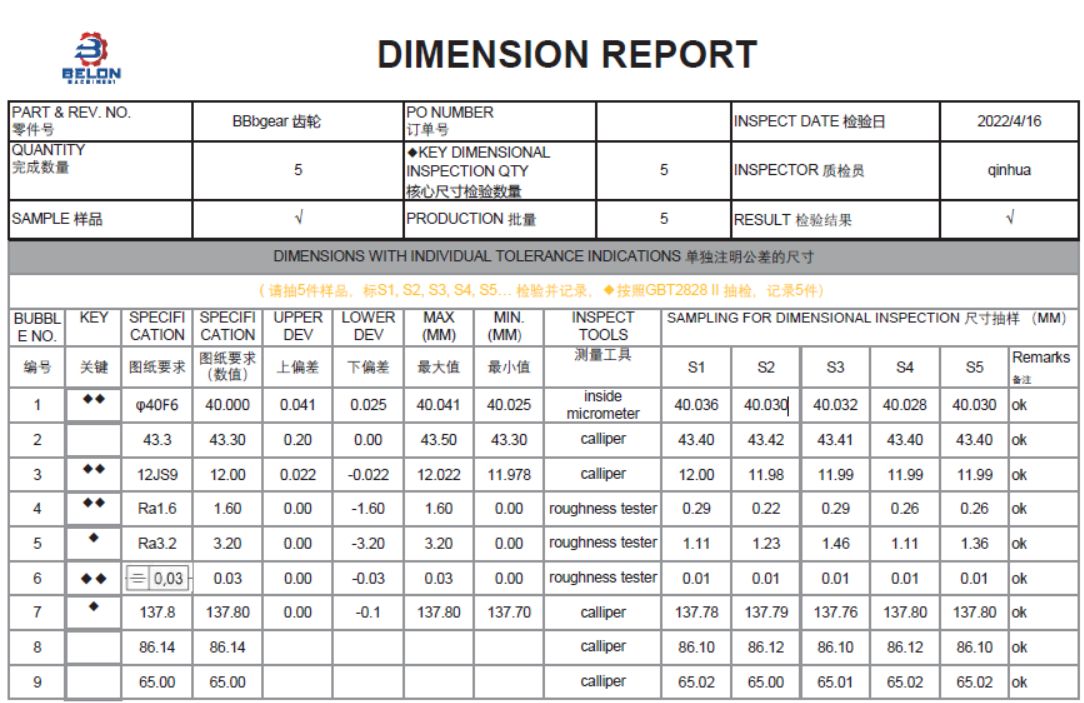

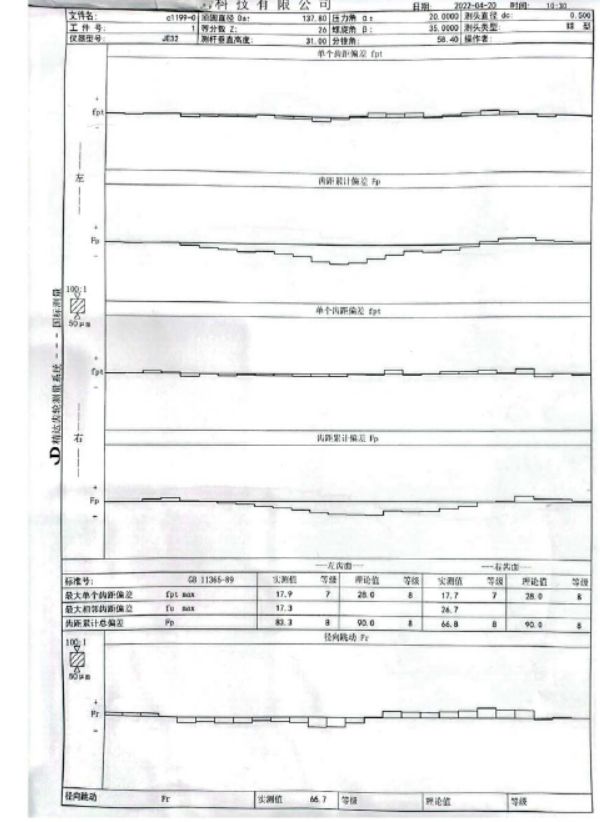

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

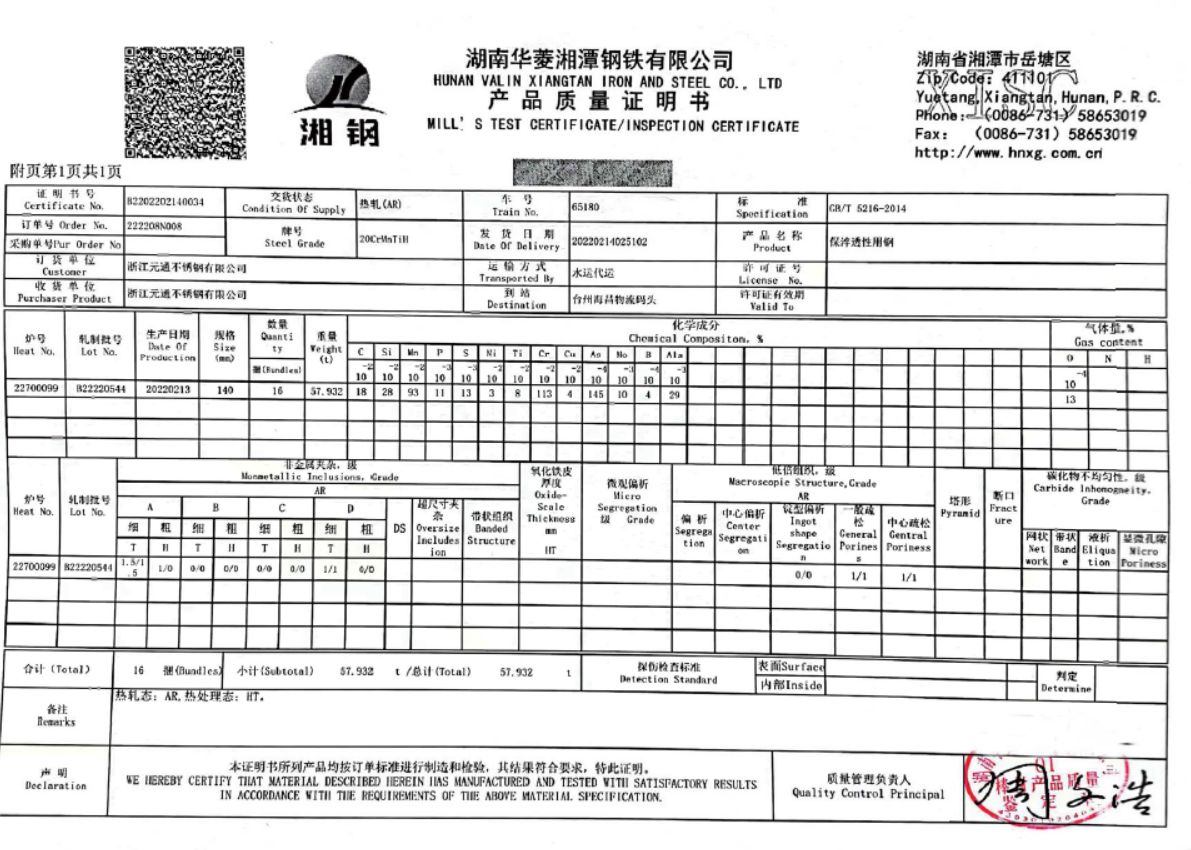

raw material

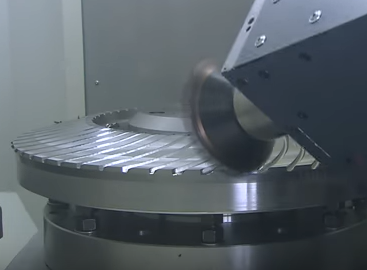

rough cutting

turning

quenching and tempering

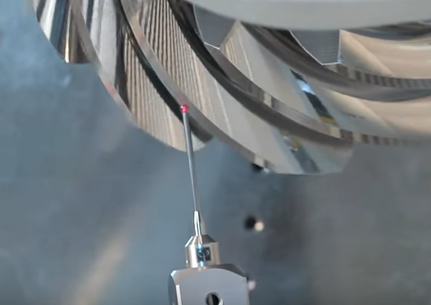

gear milling

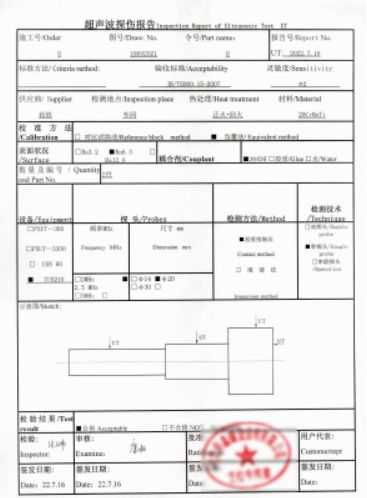

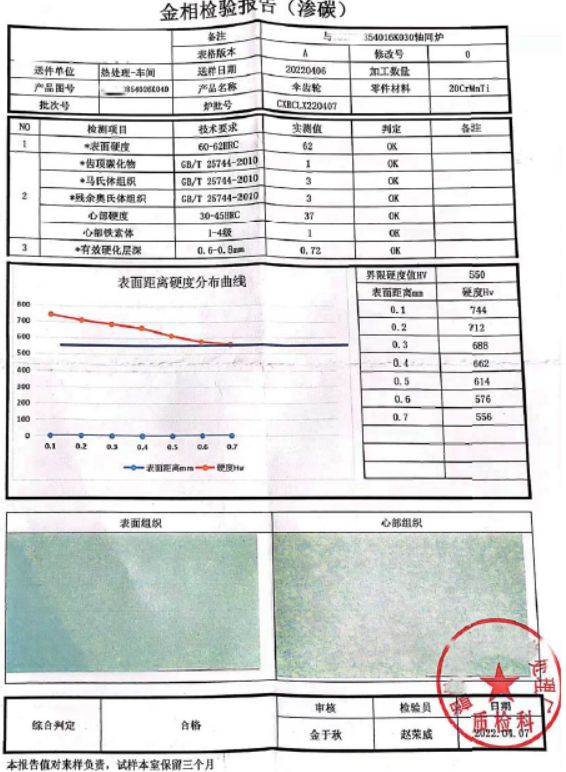

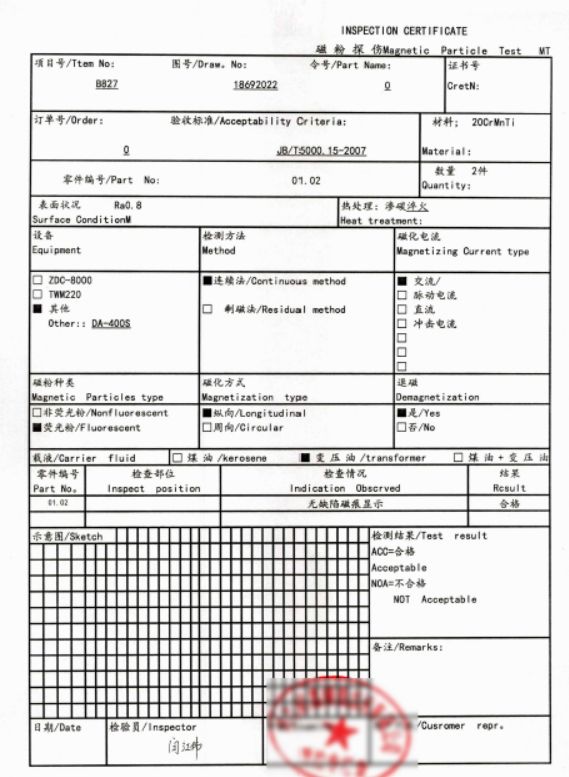

Heat treat

gear milling

testing