Top Quality 90 Degree Gear - High precision conical pinion gear used in gearmotor – Belon Detail:

Production Process:

We supplied different types of conical pinion gears from range from Module 0.5, Module 0.75,Module 1 ,Moule 1.25 mini gear shafts.

Production Process of the conical pinion shaft :

All production was done in house from forging to the finish parts .Process inspection has to be done during every process and make records . The details processes are as below :

1)16MnCr5 alloy steel material cutting plus normalizing

2)Lathe machining into rough dimensions

3)First time hobbing

4)Carburizing 58-62HRC

5)OD grinding to finish dimensions

6)Second time hard-hobbing to required accuracy

7)Final inspection

8)Clear and package and mark

Manufacturing Plant

Manufacturing Plant :

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

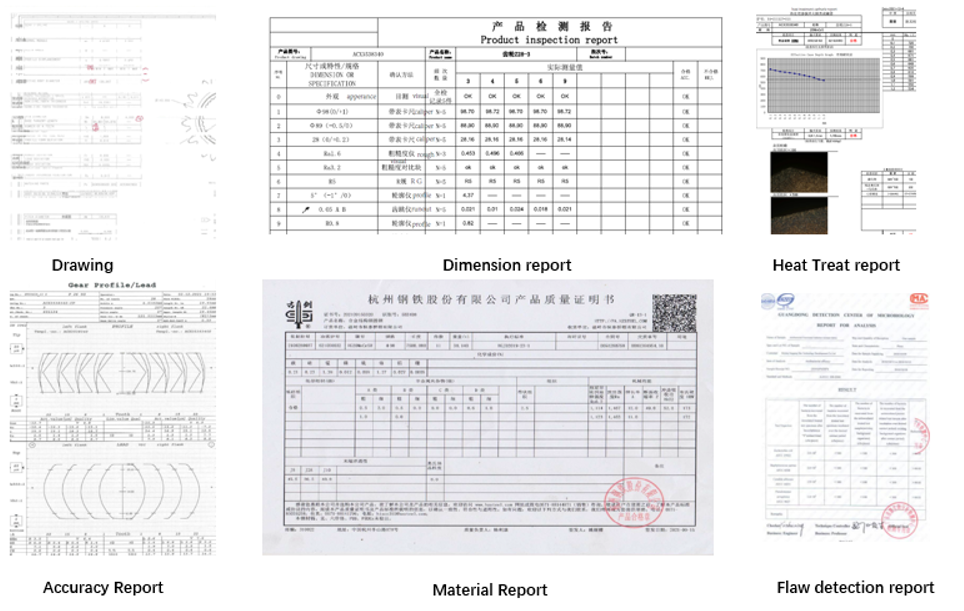

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Reports

We will provide below reports also customer’s required reports before every shipping for customer to check and approve .

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Small helical gear motor gearshaft and helical gear

Left hand or right hand helical gear hobbing

Helical gear cutting on hobbing machine

Helical gear shaft

Single helical gear hobbing

16MnCr5 helical gearshaft & helical gear used in robotics gearboxes

Helical gear grinding

Worm wheel and helical gear hobbing

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Top Quality 90 Degree Gear - High precision conical pinion gear used in gearmotor – Belon , The product will supply to all over the world, such as: Bangalore, Puerto Rico, Las Vegas, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!