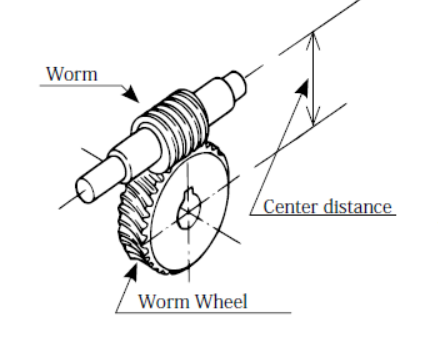

Worm gears features:

1. Provides large reduction raios for a given center distance

2. Quite and smooth meshing action

3. It is not possible for a worm wheel to drive a wor unless certain conditions are met

Worm gear working principle:

The two shafts of the worm gear and worm drive are perpendicular to each other; the worm can be regarded as a helix with one tooth (single head) or several teeth (multiple heads) wound along the helix on the cylinder, and the worm gear is like an oblique gear, but its teeth enclose the worm. During meshing, one rotation of the worm will drive the worm wheel to rotate through one tooth (single-end worm) or several teeth (multi-end worm).rod), so the speed ratio i of the worm gear transmission = the number of heads of the worm Z1/the number of teeth of the worm wheel Z2.