Marine Winch Gears

Marine winch gear is an important part of any marine winch system. These gears are designed to provide the necessary power and torque to operate the winch effectively in a marine environment. The gears in a marine winch are critical for transmitting power from the motor to the drum, allowing the winch to pull in or pay out cable or rope as needed.

Marine winches are commonly used on ships, ships and offshore platforms for a variety of purposes including anchoring, mooring, towing and lifting heavy objects. The gears in marine winches are specifically designed to withstand the harsh conditions of the marine environment, including exposure to salt water, high humidity and extreme temperatures. They are usually made from high-quality materials such as stainless steel or corrosion-resistant alloys to ensure durability and reliability.

Marine winches require gear to efficiently handle heavy loads and perform required operations. Whether pulling an anchor, towing another vessel or lifting heavy equipment, the gears in a marine winch are critical in providing the mechanical advantage needed to complete these tasks. Without gears, the winch would not be able to generate enough power to perform these functions efficiently.

The gears in a marine winch also play a vital role in controlling the speed and direction at which cables or ropes are pulled in or out. By using different gear ratios, the winch can achieve the required pulling power or speed, making it a versatile and adaptable tool for a variety of marine applications.

In conclusion, marine winch gear is an integral part of the winch system, allowing it to operate effectively in the harsh marine environment. Its rugged construction and ability to handle heavy loads make it essential for the smooth and reliable operation of marine winches in a variety of marine applications.

Propulsors Gears

Thrusters are important components in a variety of marine and aerospace applications, providing the necessary thrust for propulsion. These devices are commonly used on submarines, ships, and aircraft, and often require gear to operate effectively.

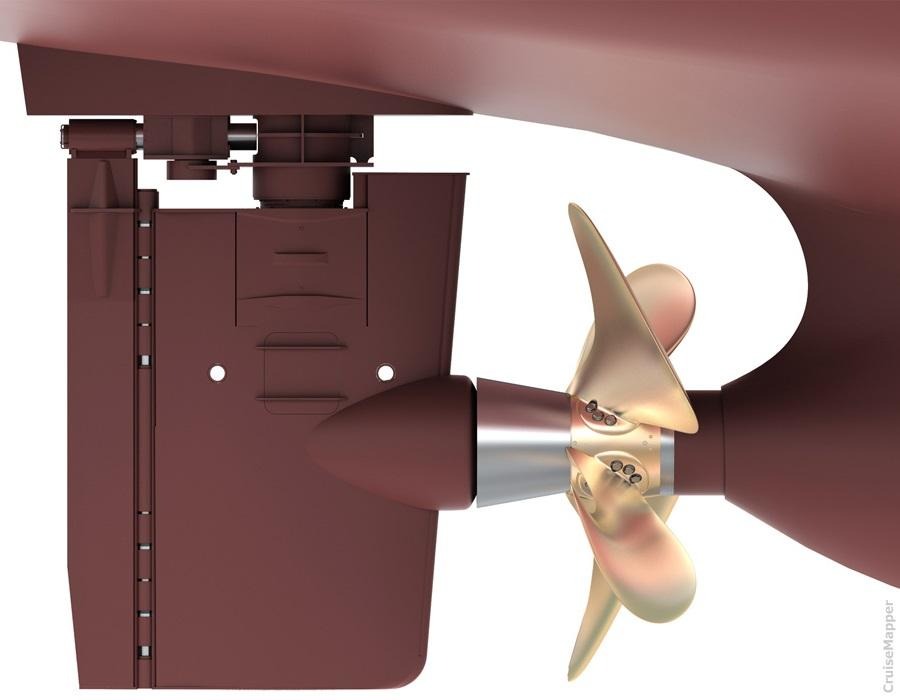

In the marine industry, propellers such as propellers and waterjets are used to propel ships and submarines through the water. Gears play a vital role in these propellers, transferring power from the engine to the drive shaft, allowing for efficient propulsion. The gears in marine propellers are designed to withstand high torque and loads while ensuring smooth and reliable operation.

In marine applications, thruster gears are strategically positioned in the propulsion system to optimize power transfer and ensure smooth operation. These gears are often precision engineered to minimize noise, vibration and wear, thereby increasing the overall efficiency and service life of the thruster system.

The integration of gears within the thruster is critical to achieving the performance and efficiency required for marine applications. Transmitting power from a ship's engine to a propeller, propeller gears play a vital role in ensuring reliable, efficient propulsion.

Marine Engine Gears

Marine engine gear is an important part of any ship and plays a vital role in the propulsion and maneuvering of the ship. These gears are necessary for various functions, and they are found in different parts of the marine engine system.

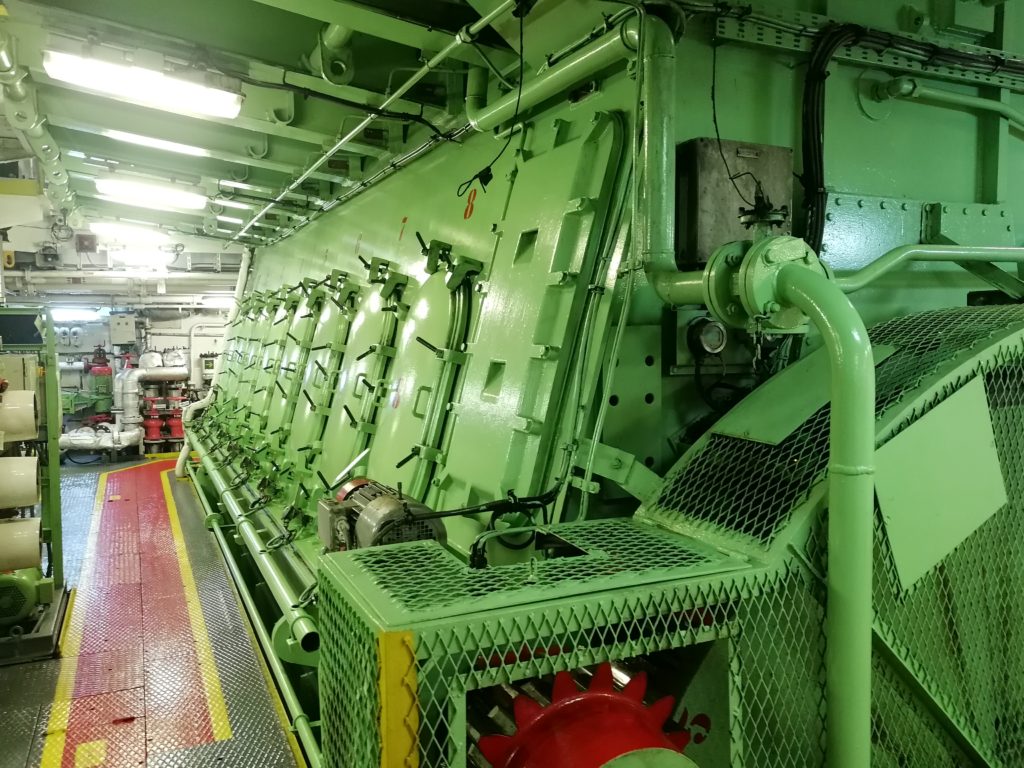

One of the main areas where marine engine gear is needed is the transmission system. The transmission system in a marine engine is responsible for transmitting power from the engine to the propeller, allowing the boat to move forward or backward. Gears are used to control the speed and direction of the propeller, allowing the ship to move efficiently through the water.

In addition to the transmission system, marine engine gears are also essential in the reduction gear system. Reduction gears are used to reduce the speed of the engine's output shaft so that the propeller runs at optimal speed for maximum efficiency. These gears help convert the engine's high-speed rotation into the slower, more powerful rotation needed for propulsion.

Additionally, marine engine gears are critical to the ship's steering system. Gears are used to control the movement of the rudder, which is essential for steering and maneuvering the ship. By adjusting the gears, the captain can change the direction of the rudder, allowing for precise navigation and control of the vessel.

Overall, marine engine gear is integral to the proper operation of your ship. They are vital in gearboxes, reduction gears and steering systems and play a vital role in a ship's propulsion and maneuverability. Without these gears, marine engines cannot run efficiently, underscoring the importance of this component in the maritime industry.

Crane Gears

Marine cranes are vital equipment used in a variety of offshore operations, including loading and unloading cargo, handling heavy equipment and supporting offshore construction activities. These cranes rely on complex gear systems to ensure smooth and efficient operation in challenging marine environments.

Gears play a vital role in the functionality of marine cranes. They are used to transmit the power of the crane motor to the hoisting mechanism, allowing precise and controlled lifting and lowering of heavy objects. Additionally, the crane’s slewing mechanism uses gears, allowing it to precisely rotate and position loads.

The marine environment presents unique challenges that require the use of specialized gear in marine cranes. Exposure to salt water, high humidity and corrosive elements requires gears to be made from durable and corrosion-resistant materials. Stainless steel and other non-corrosive alloys are often used to ensure the longevity and reliability of gears in marine crane applications.

Additionally, the heavy-duty nature of offshore crane operations requires gear that can withstand high loads and operate in challenging conditions. Gears must be designed to withstand the enormous forces involved in lifting and moving heavy cargo, as well as the dynamic loads experienced during offshore operations.

In addition to operational aspects, the safety of marine cranes relies heavily on the performance of the gears. Properly functioning gear is vital to preventing accidents and ensuring safe cargo handling, especially in rough sea conditions.

Overall, marine cranes require specially designed gear to meet the needs of the marine industry. These gears must demonstrate exceptional strength, durability and corrosion resistance while also delivering precise and reliable performance to support the critical functions of marine cranes in a variety of offshore operations.