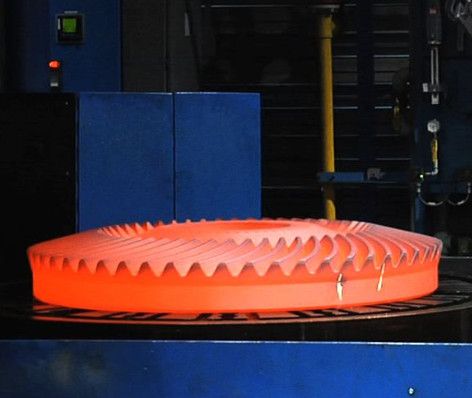

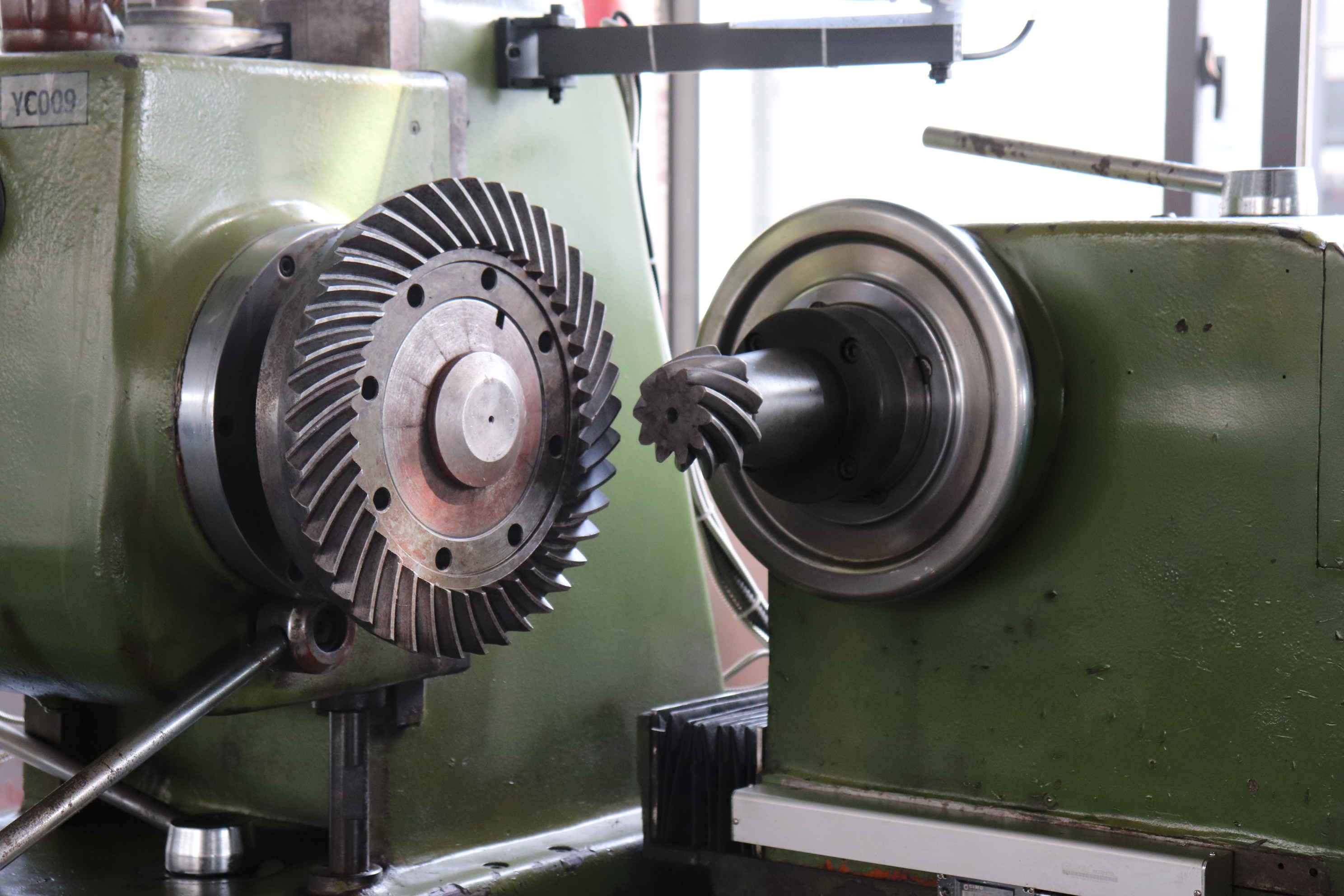

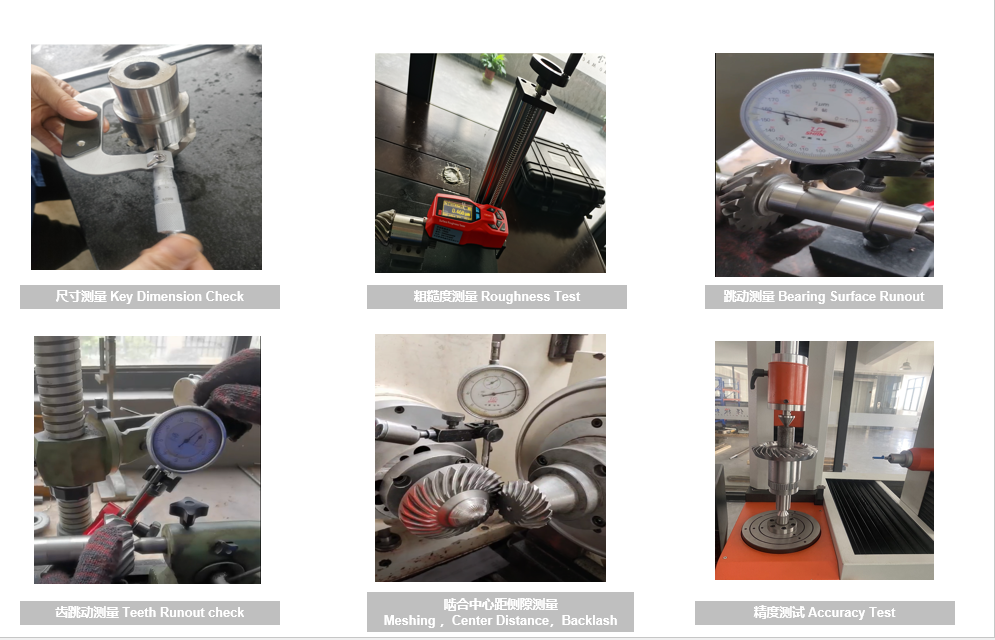

Straight bevel geaar set for construction gearbox ,Construction gears manufacturer in construction machinery, these gear sets play a pivotal role in applications like power steering systems, excavators, and drive systems, providing precise motion control and dependable performance under heavy loads. Manufactured from high-strength materials, such as alloy steel, and subjected to advanced heat treatment processes, these gears exhibit excellent resistance to wear, impact, and harsh working environments.

The straightforward geometry of straight bevel gears makes them cost-effective and easier to maintain, reducing downtime in critical operations. Their ability to operate under high torque and at various speeds ensures versatility across a wide range of construction equipment.

Whether used in cranes, loaders, or mixers, a high-quality straight bevel gear set enhances machine performance, reliability, and durability. Proper lubrication and maintenance further extend their service life, making them a trusted choice for the demanding conditions of construction sites.